Automatic Vibrating Waste Cleaner HengLi

Product video

Basic Function

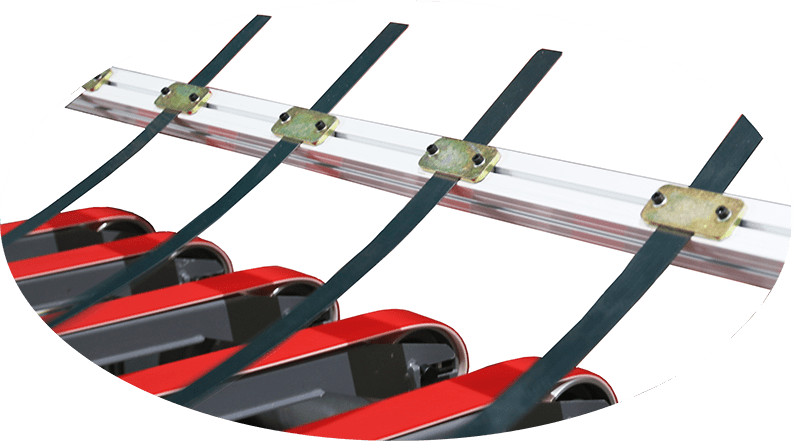

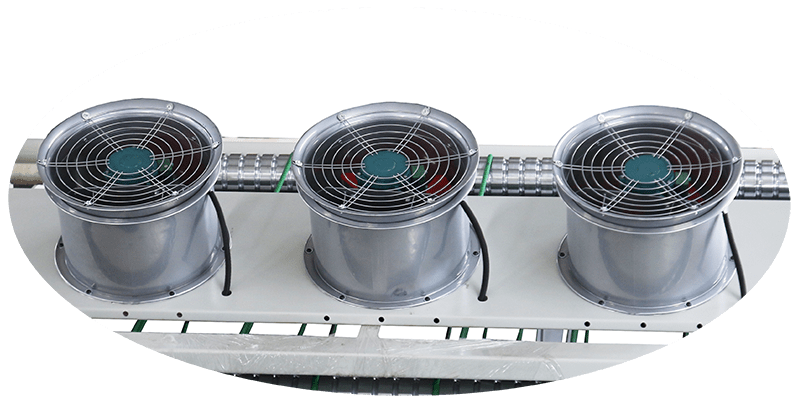

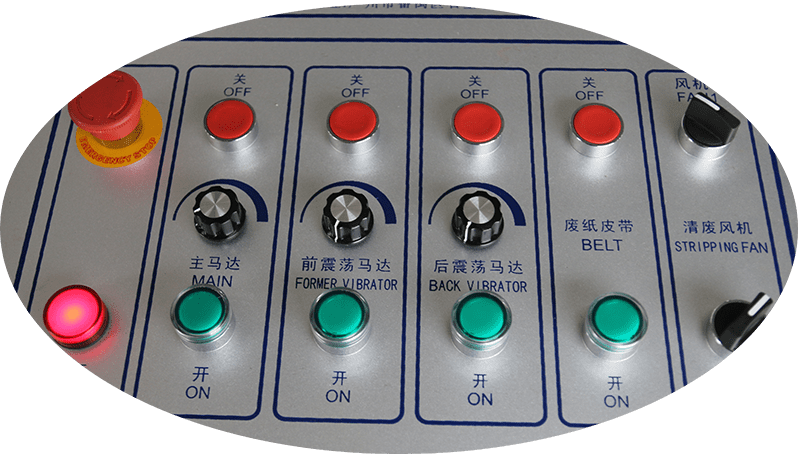

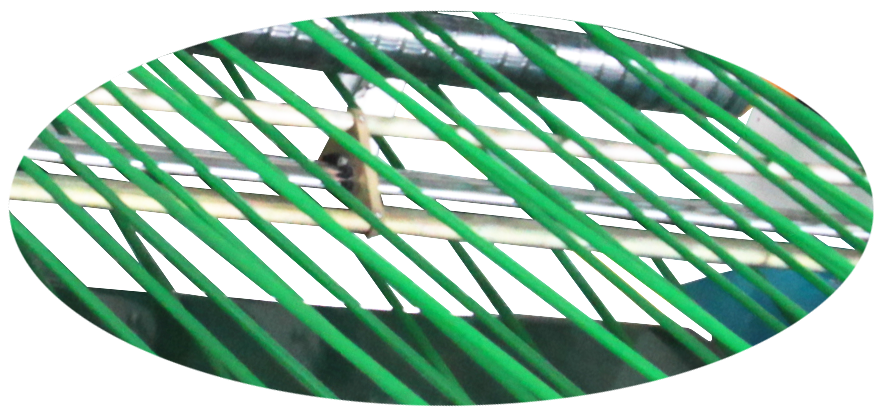

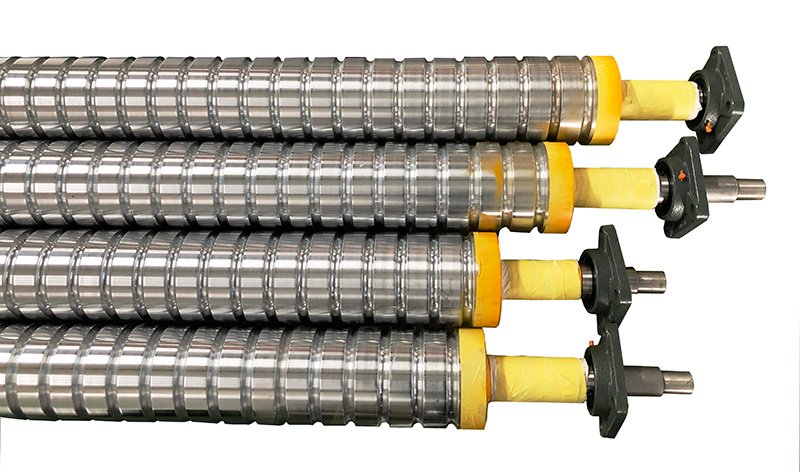

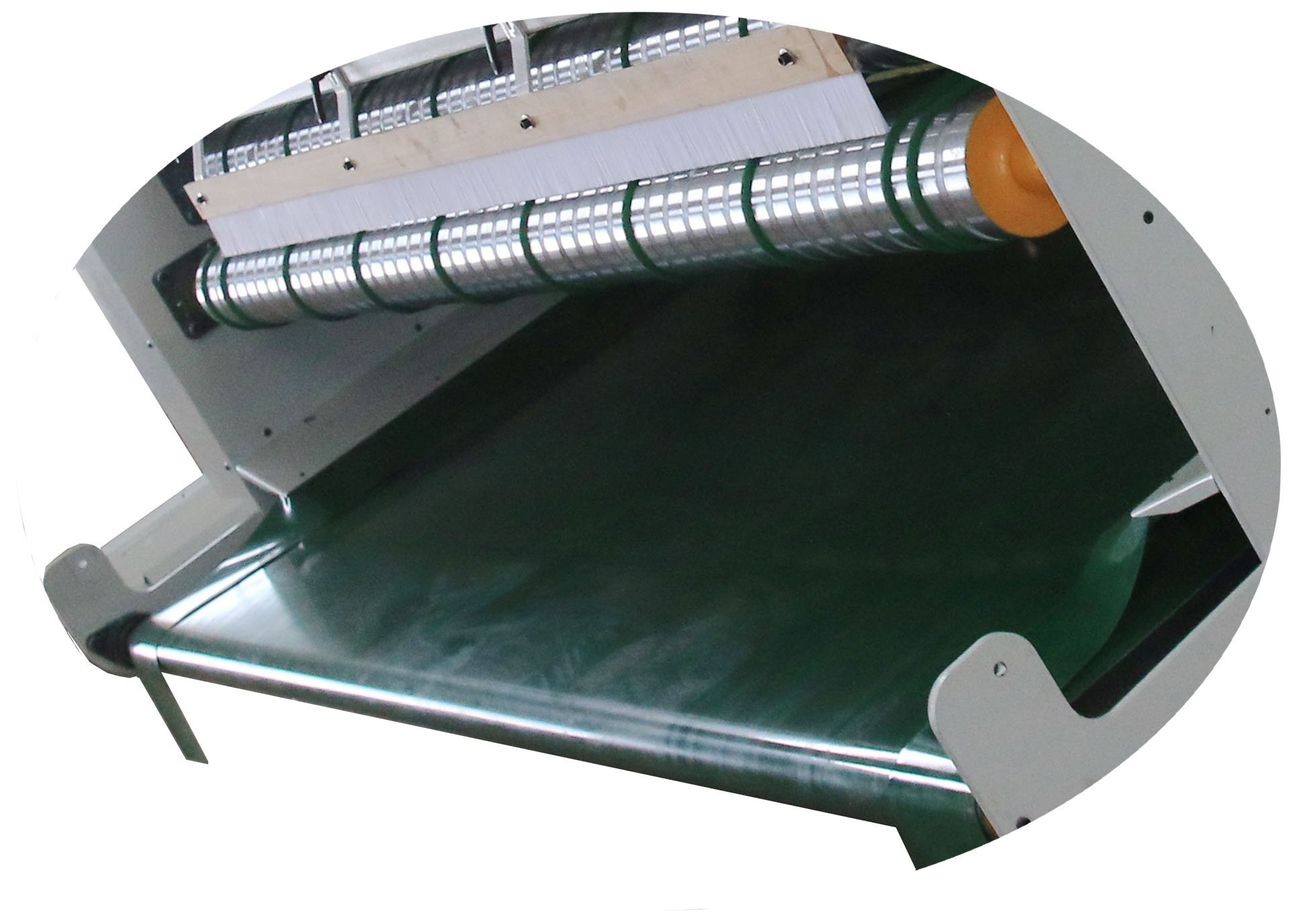

The cardboard out from die cutting machine, will go through three cleaning structure, the front end cardboard receiving platform matched with the iron trim strip mechanism, can make the cardboard be conveyed in fast and smoothly, at the same time the axial fan on the rear-end of the cardboard receiving platform will start the first time to clean up the scraps of cardboard cartons. Through cleaning waste machine two different frequency and different amplitude dithering mechanism matched with cylinder fan which on the top of cleaner machine, will realize the second time cardboard scraps cleaning. Finally, the fixed adjustable brush device on the outlet end of cleaner machine can bring away the rest of waste paper, and achieve the best effect of cleaning waste paper.

| Type | Unit | HL-VS1220# | HL-VS1224# | HL-VS1628# |

| Normal Stacking Max Speed | M/min | 250 | 250 | 180 |

| Max Sheet Size | mm | 1200 x 2200 | 1200 x 2400 | 1600 x 2800 |

| Min Sheet Size | mm | 400 x 700 | 400 x 700 | 400 x 700 |

| Covering Area(L x W x H) | mm | 3960 x 3440 x 1600 | 3960 x 3840 x 1600 | 3960 x 4040 x 1600 |

| Weight | kg | 2160 | 2360 | 2660 |

| Power | kw | 8.8 | 8.8 | 8.8 |

| Voltage of Produc | V/HZ | 380V/50HZ 3Phrase | 380V/50HZ 3Phrase | 380V/50HZ 3Phrase |

| Paper receiving height | mm | Customized | Customized | Customized |

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts