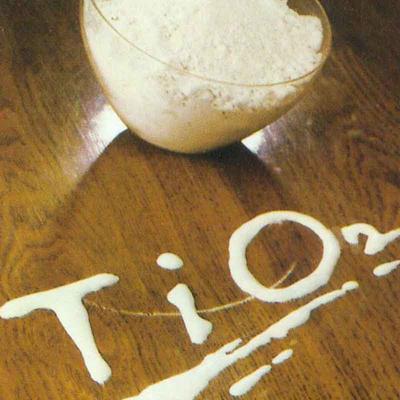

Base Powder Coating and top clear varnish protection coating for Auto-part KINTE

Product fetures

◪ Smooth appearance

◪ Strong adhesion

◪ Good resistance to salt spray

application areas

Details

Kinte has been developing the Special Powder Coatings for Aluminum Wheel-Hub since 1997. Now, we are the largest powder Coatings supplier in the Chinese Aluminum Wheel-Hub field, with a market share of more than 40%.The annual output of Chinese Wheel-Hub is more than 120 million pieces, with the three former manufacturers accounting for 50%. They all mainly use Kinte powder coatings ,Our clients including DICASTAL WHEEL ,ZHONGNAN ALUMINUM WHEEL, WANF FENG WHEEL ,LIZHONG WHEEL,these wheel companies are main suppliers for BMW, Mercedes, Audi, Volkswagen, Opel, GM, Ford, Toyota, Honda and Nissan etc Introduction: This series of special powder coatings for aluminum wheel-hub is designed by our company for inner wheel-hub protection and surface vanish. It has the features of smooth appearance, strong adhesion, good resistance to salt spray and complete free polish of the base powder. Our products have been widely adopted by well-known brand car company and wheel-hub manufacturer in both domestic and overseas market.

Series of products

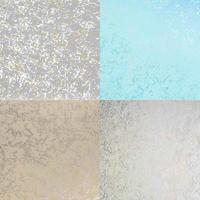

① Clear Powder Coatings

Acrylic clear powder

Super-high transparent pure polyester powder coatings(latest product)

Standard transparent pure polyester powder coatings

② Base Powder

High leveling pure polyester base powder

High leveling epoxy/polyester base powder

Super-high leveling and high gloss epoxy/polyester base powder

Super-high leveling and low gloss epoxy/polyester base powder

Special function products (Breathing powder coatings、Electrostatic shield resistance powder coatings)

Property

Density: 1.2~1.8g/cm3( Ingredient and color demand)

Particle size: Purpose demands, standard granularity is 35-40 um, <10um powder <10%, >90um powder <0.5%.

Storage stability: This series of special powder coatings for aluminum wheel-hub should be stored below 35°C in a dry and well ventilated place away from source of heat, ignition and direct sunlight. If stored in an air-conditioner room, in order to avoid damp again, before using the powder, the powder should be kept at the room temperature or at the same temperature with the spray equipment. Under such condition, the powder can be stored stably for 12 months.

Extended, retest will be required. If the testing result meets the requirement, the powder can still be used.

Film Characteristics of acrylic clear powder and pure polyester clear powder

Properties | Method | Value |

Appearance | Visual | Various |

Impact | ASTM D-2794-93 | 1Kg*50cm |

Flexibility | ASTM D-522-93 | 1/8’’No cracks |

Adhesion | ASTM D-3359-95B | 0 Grade |

Pencil Hardness | ASTM D-3363-92 | >1H |

Cupping Test | GB/T 9753-1988 | ≥6mm |

Salt Spray | ASTM B-117-97 | ≥1000h no effect,and the corrosion width of the cross is no more than 2mm |

CASS Salt Spray | General Motors GM4476P | One side corrosion width Wb≤3mm |

Filiform Corrosion Resistance Test | General Motors GM9682P | One side corrosion width Wb≤3mm |

Gravel Impact | General Motors GM9508P | ≥6 Grade |

Gel Test | General Motors GM4465P | No corrosion and no bubble of the base metal |

Solvent Test | General Motors GM9509P | ≤2 Grade |

Xenon Lamp Aging Test | General Motors GM9125P ASTM G151/ GB/T1865-1997 | 1000h(Pure polyester type),1500h(arcelic clear powder)gloss retention≥80% no significant color change |

Natural Exposure | GB/T 9276 | 1 year,gloss retention ≥80%,no significant color change |

Film Characteristics of Special Base Powder

Adhesion | ASTM D-3359-95B | 0 Grade | |

Flexibility | ASTM D-522-93 | 1/8’’ no cracks | |

Pencil Hardness | ASTM D-3363-92 | >H | |

Impact | ASTM D-2794-93 | 1Kg*50cm | |

Salt Spray | ASTM B-117-97 | ≥1000h,Wb≤2mm | |

Water Resistance | General Motors GM 9071P | 1000h,no bubble, Adhesion 0 grade | |

CASS Salt Spray | General Motors GM4476P | 240h Wb≤3mm | |

Humidity | ASTM D-2247-94 | ≥1000h,no bubble、slight loss of light of the film | |

Adhesion of The Balance Block | VolkswagenTL239 | ≥50N/mm2 | |

Film property above may decrease slightly while the gloss decreases. | |||

Curing Guide | Suggestion:180℃/10mins or 160℃/20mins for acrylic clear powder coating,200℃/10mins or low temperature curing 180℃/10mins for pure polyester clear powder coating,180℃/8-12mims for base powder、150℃-160℃ /10-15mins for low temperature curing base powder. | ||

Packing & Powder flowchart

Contact

Supplier