Heat transfer wooden effect Powder Coating manufacturer

Product introduction

It’s a kind a powder coating that with special purpose, specifically used for base film of thermal transfer technology coating. With heat thermal transfer technology, all kinds of appearance effects can be formed on the powder film, such as wood , marble vein and other effects.There are 2 kinds of heat-transfer powder coating :Polyester type based on TGIC hardener and Polyurethane type based on blocked isocyanate hardener.Regards of Polyurethane type.

PROPERTIES | Specific Gravity | 1.4~1.8g/cm3(It varies according to the different formula and different colors) | |||

Particle Size | Standard particle size of average is35~40μm,the amount of less than 10μm is<10%,and the amount of more than 100μm is<0.5%.If there is special demand, please advise in advance | ||||

Flowing | Good flowing and conveying | ||||

Softening Point | 70~105℃.It varies according to the different colors and gloss | ||||

Storage Stability | 12 month within 30℃ | ||||

PROPERTIES OF COATING

| Test Items | Test standard and method | Value | ||

Appearance | Visual inspection | A variety of coating effect | |||

Impact | GB/T 1732-1993 | ISO 6272 | 1Kg*50cm | ||

Flexibility | GB/T 6742-1986 | ISO 1519 | ∮2mm | ||

Cupping | GB/T 9753-1988 | ISO 1520 | ≥8mm | ||

Adhesion | GB/T 9286-1998 | ISO 2409 | 0 grade | ||

Hardness | GB/T 6739-2006 | ASTM D3363 | H~2H | ||

Salt Spray | GB/T 1771-2007 | ISO 7253 | ≥500 h | ||

Humidity | GB/T 1740-2007 | ISO 6270 | ≥1000 h | ||

QUV article aging test | GB/T1865-1997 | ASTM G151 | 1000h | ||

The above properties of coating might reduce slightly with the reducing of the gloss | |||||

Spraying | This series product is suitable for the following spraying methods:corona electrostatic spraying, friction electrostatic spraying, electrostatic fluidized bed spraying,fluidized bed thermal spraying and other spraying methods(For the last 3 methods, please requested in advance) | ||||

Film thickness :40~150μm, theoretically50~80μm. Average coverage: 10~12m2/Kg, film thickness 60μm(Calculated at the usage rate of 100%) | |||||

Curing guide | Theoretical200℃/10min | ||||

Product fetures

◪ Good leveling,clear veins,easy to tear the printing fill,good permeability, slight diffusivity

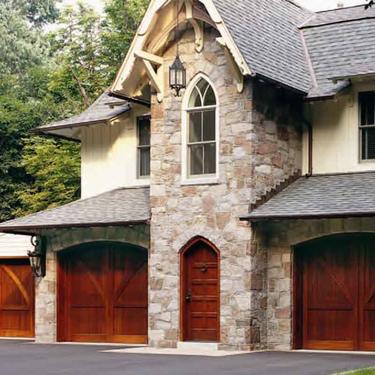

◪ All kinds of appearance effects can be formed on the powder film, such as wood , marble, vein,and our base powder has metallic effect, pearlescent effect and compound colors

application areas

Packing & Powder flowchart

Contact

Supplier