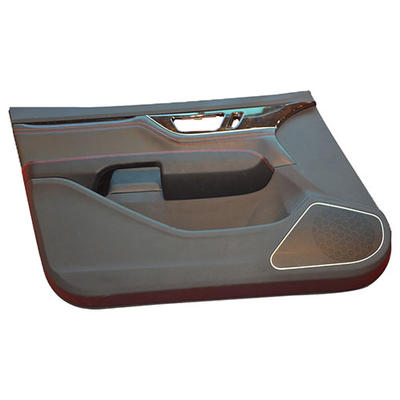

Car parts by vacum casting

The vacuum casting technology uses a prototype of the product (rapid prototype, cnc prototype) to make a silicone mold under vacuum, and uses a PU material to be poured under vacuum, thereby cloning the same replica as the prototype. The vacuum casting technology can be applied to change the material of the prototype, assemble the prototype or carry out small batch production of the product to meet the requirements of performance testing, marketing, inspection and approval in the product development process.

Name | Original Colour | Characteristics |

Baked Porcelain | Transparent | Similar to PMMA, crisp transparency, non-resistant to |

PX-100 | Ivory | Similar to ABS, general toughness, temerapature resisitant |

PX-100 | Black | Similar to ABS, general toughness, temerapature resisitant |

PX-210 | Transparent | Similar to PC, good toughness, strength and shape |

PX-215 | Ivory | Similar to ABS, general toughness, temerapature resisitant |

PX-226 | White | Good shape retention, high temperature resistence, |

PX-521 | Transparent | Similar to PC and PMMA, malleable, hard, |

PX-522 | Transparent | Similar to PC and PMMA, malleable, hard, |

PU-4280 | Beige | Similar to ABS, good toughness, low shrinkage, |

PU-5672 | White | Similar to PP, high shock resistance, low shrinkage, |

PU-5673 | White | Similar to PP, high shock resistance, low shrinkage, |

PU-6160 | White | High temperature resistance, easily painted, very high |

PU-8260 | White | Similar to ABS, general malleability, flame retardent |

PU-8901 | White/Black/Transparent | Similar to ABS, general malleability, hard and tough, |

PU-8400 | White/Black | Similar to EDPM rubber, can be painted, colours can |

PU-8012 | Yellow | Similar to ABS, low toughness, crisp |

PU-8014 | Ivory | Similar to PU-8012, characteristics slightly better, |

PU-8150 | Off White | Similar to ABS, tough, temperature resistant up to |

DPI-041 | Transparent Rubber | Easily operable, good malleability, prone to |

DPI-700 | Black Rubber | Similar to ABS, good shape retention, tough, hard, |

DPI-090 | Transparent Rubber | Similar to ABS, good shape retention, tough, |

DPI-410 | White Rubber | Similar to PP/PE, good shape retention, tough, |

DPI-035 | Transparent Rubber | Low discolouration, easilily operable, tough |

DPI-430 | White Rubber | Similar to ABS, tough, malleable, hard |

Silicon Rubber | T-4 | Transparent, low shrinkage, durable, ok up to 18 |

Silicon Rubber | 8678 | Transparent, good elasticity, ok up to 15 |

Silicon Rubber | 803 | Ivory white, high shrinkage, durable, ok up to 12 |

Silicon Rubber | 300# | Ivory white, low shrinkage, durable, ok up to 12 |

◪ Before the production of Vacuum Casting, we need to make a sample by CNC machining or 3D printing.

Then mix silicone with curing agent. The appearance of Vacuum Casting is a flowing liquid, component A is Silicone, component B is a curing agent.

◪ Vacuum evacuations:

After the silicone and curing agent are mixed evenly, vacuum evacuation is performed. The time for vacuuming should not be too long. Under normal circumstances, do not exceed 10 minutes. If the vacuum is too long, the silicone will cure immediately. The cross-linking reaction was produced so that the silica gel became one piece and could not be painted or poured.

◪ Brushing or operation process:

Pull the evacuated silicone on the sample by brush or pour. (Note: The product or model to be copied need to use release agent before pour the silicone). Then brush the silicone on the top of the product, brushing must be uniform, after 30 minutes, paste a layer of gauze fiber weft cloth to increase the strength and tensile of silicone.

◪ Outer mold production:

Generally used methods and materials are surrounding the mold by a plastic sheet or wood, then fill mold cabinet with plaster. Another method is to brush a layer of resin then paste a layer of glass fiber cloth, then brush and then paste, repeated two or three layers can complete the mold outside.

◪ Filling or pouring mold operation method:

Filling or pouring mold is used for relatively smooth or simple products, no mold line save time and labor.

Contact

Supplier