CNC gantry milling CNC lathe machining center SNK-1612

SNK-1612 gantry milling technical

High speed, high efficiency, high precision and reliable

Through multiple heat treatment, high precision effectively for a long time, to ensure the high accuracy displacement performance

Superposed knife library, tool change speed agility, improve the production efficiency and reliability

With high precision automatic instrument on the knife, improve the efficiency of the machine.

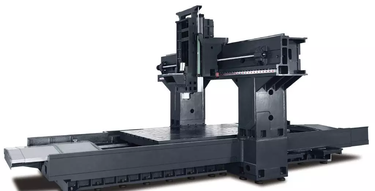

SNK-1612 gantry processing center

The gantry machining center adopts the workbench mobile, beam fixed gantry frame structure,

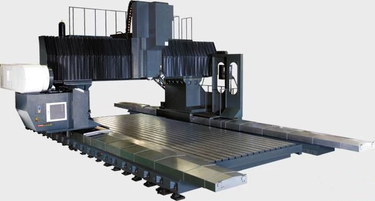

widely used in automotive, aerospace, printing and packaging, textile machinery, metallurgy,

petrochemical, locomotive, mold and other large and medium-sized machinery parts

processing and mould manufacturing industry, a clamping can meet the requirements of coarse,

half finishing and processing, can finish milling, drilling, nine, boring,

reaming, and other processes.

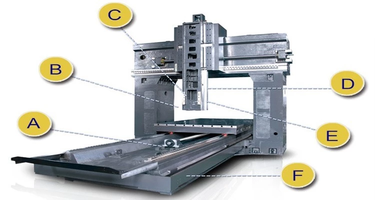

Main structural features

540/5000

HT300 cast iron is adopted for the base, worktable, pillar, beam, slide seat, spindle box and

other major foundation pieces. The cabinet models , compact and reasonably symmetrical

steel structure guarantee the high rigidity and bending and damping

performance of the foundation pieces. The base parts are made of resin sand and experienced aging treatment,

which provides a guarantee of the stability of the machine tool's

long-term performance.

Both X and Y directional guides are heavy-duty linear guides of 55 specifications imported, with features of

fast speed, high rigidity, low friction, low noise and low temperature rise and change; The z-direction

is the broadened rectangular sliding guide rail, and through high frequency fire

and precision grinding, the sliding guide surface is coated with composite PTFE material and precision scraping and grinding,

which is combined with automatic forced lubrication to improve the precision life

and rigidity of the machine tool.

Z drive motor has power loss braking device;

X, Y and Z three directions adopt high rigidity double nut prepress P3 large lead screw with P3 level, high feed speed;

Adopt high speed, high precision and high rigidity heavy load spindle unit produced by Taiwan professional manufacturers,

with strong axial and radial bearing capacity and a maximum speed of 6000rpm;

The spindle adopts a central air blowing structure, which can quickly clean the inner cone of the

spindle with the central high pressure gas when the spindle is punched, so as to ensure the

accuracy and service life of the spindle and tool.

X, Y and Z direction guide rails and lead screws are protected by protective devices to ensure the

cleaning of lead bars and guide rails, and to ensure the transmission and movement accuracy

and life of the machine tools;

Reliable centralized automatic lubrication device is adopted to automatically intermittently

lubricate all lubrication points on the machine tool regularly and quantitatively, and the lubrication time can be adjusted

according to the working conditions;

The machine tool operating system adopts ergonomic principle, and the operating box is independently

designed, which can rotate itself and operate conveniently.

rate conveniently.

MODLE | 1612 |

WORKING TABLE SIZE(MM) | 1600mm X 1200mm |

X-TRAVEL | 1700 |

Y-TRAVEL | 1200 |

Z-TRAVEL | 750 |

WIDE | 1700 |

SPINDLE DIAMATER | 190 |

TOOL MODLE | BT50 |

SPINDLE POWER RATED | 15 |

DISTANCE BETWEEN SPINDLE AND WORKING TABLE | 100-850 |

X-AXIS FEEDING RATE | 12000 |

Y-AXIS FEEDING RATE | 12000 |

Z-AXIS FEEDING RATE | 12000 |

CUTTING FEEDING SPEED | 8000 |

X/Y AXIS LINER GUIDEWAY | 55# |

X-AXIS SCREW | 5010 |

Y-AXIS SCREW | 5010 |

Z-AXIS SCREW | 5010 |

POSITIONING ACCRUCARY | 0.02/500 |

REPEAT POSITIONING ACCRUCARY | ±0.01mm |

MACHINE SIZE | 3000mm x 4200mm x 4500mm |

MACHINE WEIGHT | 12000kg |

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts