Cnc Industrial DRILLING AND TAPPING MACHINE SNK-T6

Drilling and tapping machine

High speed, high efficiency, high-precision, reliable

With multiple heat treatments, the accuracy of the whole machine is applicable for a long time, it can ensure high precision displacement performance.

Front-mounted tool holder, quicken tool change speed, improve production efficiency and reliability effectively.

Adopt high precision automatic tool setting instrument to increase the efficiency of adjustment.

Scope of application

Precision parts processing industry: CNC drilling, milling and milling of steel parts, aluminum parts, hand model;

Glasses Industry: steel work, copper work, metal frame, plastic frame, inner pit, light shape, carving pattern and other accessories processing;

Watch industry: glass position, pressing position, the wire hole position, curved surface, arc surface drilling, rose tooth, engraving text and other processing.

Features

Optional or retrofit: system, tool magazine, four-axis, five-axis, etc. It can quickly complete the drilling, milling and engraving of planes, solid surfaces and

three-dimensional shapes; automatic fast tool change system, support multi-axis linkage and rotary angle processing, and can process multiple parts of the product at one

time without multiple setups. To achieve faster and more accurate processing efficiency.

The proprietary technology addresses the issue of high price of the traditional drilling and milling center machine, and can realize the ideal of low investment and high return.

1.SPECIFICATION

ITEM | UNIT | SPECIFICTION | ||

WORKING TABLE | WORKING TABLE SIZE | mm | 700*420 | |

T-SLOT(NUMBER-SIZE*DISTANCE) | mm | 14-3*125 | ||

SPINDLE SURFACE DISTANCE BETEEN WORKING TABLE | mm | 150-450 | ||

WORKING TABLE BEAR | kg | 250 | ||

SPINDLE | CONICAL PASS TYPE, INSTALL SIZE | --- | BT30 | |

SPEED | rpm | 20000 | ||

DIAMETER | mm | 100 | ||

| DISTANCE BETWEEN SPINDLE CENTER AND SPINDLE | mm | 486 | ||

TRAVEL | X-AXIS | mm | 600 | |

Y-AXIS | mm | 400 | ||

Z-AXIS | mm | 300 | ||

FAST MOVING SPEED | X-AXIS | m/min | 48 | |

Y-AXIS | m/min | 48 | ||

ZAXIS | m/min | 48 | ||

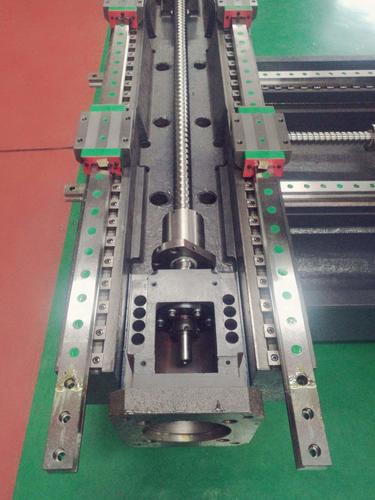

SCREW MODEL | X-SCREW MODEL | --- | 3216 | |

Y-SCREW MODEL | --- | 3216 | ||

Z-SCREW MODEL | --- | 3216 | ||

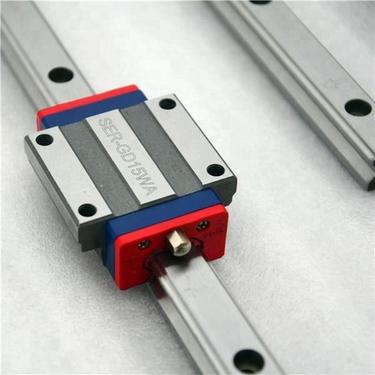

LINEAR GUIDEWAY | X-LINEAR GUIDEWAY | --- | 30 | |

Y-LINEAR GUIDEWAY | --- | 30 | ||

Z-LINEAR GUIDEWAY | --- | 30 | ||

| SPINDLE MOTOR | MOTO TYPE | FANUC ais8 | ||

MAXIMUM SPEED | 20000 | |||

RATED POWER | 5.5KW | |||

| CONNECTION WAY BETWEEN SPINDLE AND MOTOR | DIRECT CONNECTION | |||

FEEDING MOTOR |

X-AXIS | MOTO TYPE | --- | FANUC BIS8 |

MAXIMUM SPEED | r/min | 4000 | ||

RATED POWER | KW | 1.5 | ||

Y-AXIS | MOTOR TYPE | --- | FANUC ais12 | |

MAXIMUM SPEED | r/min | 4000 | ||

RATED POWER | KW | 3.0 | ||

Z-AXIS | MOTO TYPE | --- | FANUC BIS12 | |

MAXIMUM SPEED | r/min | 4000 | ||

RATED POWER | KW | 3.0 | ||

CUTTING FEED SPEED RANGE X/Y/Z-AXIS | mm/min | 0-12000 | ||

AUTOMATIC TOOL CONVERSION DEVISE | STANDARD DEVISE | UNIT | 16 | |

SHANK TYPE/ CONICAL DEGREE | --- | BT30 | ||

MAXIMUM TOOL WEIGHT | kg | ||

TOOL SELECTION MODE | --- | EXCHANGE | |

CASTING SIZE | LENGTH | mm | 1950 |

WIDE | mm | 2340 | |

HIGH | mm | 2400 | |

CASTING WEIGHT | NET WEIGHT | Kg | 3500 |

GENERRAL POWER | VOLTAGE/FREQUENCY | V/Hz | AC380/50 |

VOLTAGE FLUCTUATION RANGE | --- | 20% | |

TOTAL CAPACITY OF POWER SUPPLY | KVA | 14.5 |

2.MACHINE TOOL ACCURACY STANDARD

INSPETION ITEM | DEMAND | |

POSITIONING ACCURCY | X-AXIS | JIS±0.005/300 |

Y-AXIS | JIS±0.005/300 | |

Z-AXIS | JIS±0.005/300 | |

REPEAT POSITIONING ACCURACY | X-AXIS | JIS±0.005/300 |

Y-AXIS | JIS±0.005/300 | |

Z-AXIS | JIS±0.005/300 | |

CINNECTION MODE OF THREE-AXIS MOTOR | X/Y/Z | DIRECT CONNECTION |

3.MACHINE SPECIFICATION

NAME | SPECIFICATION TYPE | BRAND |

CONTROL SYSTEM | JAPAN/ FANUC OI-MF | |

SPINDLE | BT30 | CHINA |

X-SCREW | 3216 | TAIWAN HIWIN / PMI |

Y-SCREW | 3216 | TAIWAN HIWIN / PMI |

Z-SCREW | 3216 | TAIWAN HIWIN / PMI |

X/Y-AXIS TRACK | 30*30 | TAIWAN HIWIN / PMI |

Z-AXIS TRACK | 30 | TAIWAN HIWIN / PMI |

BEARING | NSK SPECIAL BEARING | JAPAN THT |

SPINDLE COOLING SYSTEM | QG-02LY-1P | CHINA |

LUBRICATING DEVICE | ELECTRIC LUBRICATING PUMP | CHINA |

ELECTRICAL CABINET COOLING SYSTEM | HEAT EXCHANGE | CHINA |

GENERAL ELECTRICAL COMPONNENTS | ELECTIC RELAY; CONTACT; ELECTRONIC MANETIC VALVE; | SCHNEIDER |

TOOL | BT30-16T | |

MOBILE ELECTRONIC HAND PLUSE | 1225 | CHINA |

COOLING PUMP | 750W | CHNA |

PROTECTION | FULL CLOSURE | CHINA |

4.MACHINE ACCESSORISE

NO | NAME | SPECIFICATION | QUANTITY | BRAND |

01 | WORKING LIGHT | LED220V-800MM-24W | 1 | CHINA |

02 | ADJUST THE SIZING BLOCK ADN SCREW | M30 | 6 | CHIAN |

03 | TRANSPORT FIXING | M18 | 4 | CHINA |

04 | ALARM | 24V | 1 | CHINA |

05 | UNLOADING KNIFE SEAT | BT30 | ||

06 | ELASTIC SHANK | BT30 | ||

07 | CABLE NOZZLE | ER32 | 7 | 4.6.8.10.12.16.20 |

08 | 6 INCH BATCH | OPEN | 1 | NORMAL |

09 | PLATEN | M12 | 1 | NORMAL |

10 | HARD DRIVER | 2G | 1 | NORMAL |

5.TECHNICAL SHEET

01 | INSTRUCTION MANUAL(MACHANIAL PART) | 1 |

02 | SYSTEM INSTRUCTION MANUAL | 1 |

03 | PROGRAM INSTRUCTION MANUAL | 1 |

04 | MACHINE TOOL QUALIFICATION MANUAL | 1 |

05 | MACHINE TOOL PACKING LIST | 1 |

06 | TOOL INSTRUCTION MANUAL | 1 |

07 | LUBRICATING PUMP INSTRUCTION MANUAL | 1 |

6.MAIN FUNCTION OF CONTROL SYSTEM

1 | CONTROL SERVO SYSTEM: FANUC OI-MF | 19 | GRAPHIC DISPLAY(2D) |

2 | SIMULTANEOUS CONTROL SYSTEM : FANUC OI-MF | 20 | TOOL LENGTH AND RADIUS COMPENSATION |

3 | ENGLISH/ METRIC UNIT INPUT | 21 | TOOL MANAGERMENT |

4 | ABSOLUTE/ INCREMENT INSTRUCTION | 22 | 64 SETS TOOL SPECIFICATION |

5 | MANU PROGRAM | 23 | REVERSE CLEARANCE COMPENSATION |

6 | 24 | SCREW PITCH ERROR CCOMPENSATION | |

7 | LINEAR DIFFRENCE COMPENSATION | 25 | |

8 | CIRCLE ARC DIFFERENCE COMPENSATION | 26 | SPINDLE STOP |

9 | POLAR DIFFERENCE COMPENSATION | 27 | WORK PIECE COORDINATE SYSTEM |

10 | HELIX COMPENSATION | 28 | 6 SETS OF SETTABLE ZERO OFFSET |

11 | RIGID TAPPING | 29 | PROGRAMMABLE ZERO SHIFT |

12 | FRAME FUNCTION(MIRROR、SCALING AND ROTATION) | 30 | SUBROUTINE CALL |

13 | PROGRAM STORAGE CAPACITY:640M(256k Byte) | 31 | GRAPH CYCLE SUPPORT |

14 | BACKGROUD EDITOR | 32 | PROCESSING AREA RESTRICTIONS |

15 | MDA MODE | 33 | ACCELERATED MUTATION LIMIT |

16 | 34 | SPARE PART TIMER | |

17 | 8.4 " COLORFUL DISPLAY | 35 | HARD/SOFT LIMIT SWITCH |

18 | CHINESE/ ENGLISH DISPLAY | 36 |

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts