1.The main strip material selection is based on Lanxess,Mistui,Kumho and other manufacturers of raw rubber EPDM,microwave curing process forming a production line.

2.Has good flexibility and resistance to compression,weather resistance,ozone resistance,chemical stability,excellent electrical insulation properties and wide temperature range (-50°C~+150°C),excellent performance.

3.Secondly,sponge foam has a good waterproof,dust,noise,compartment temperature,damping effect can be applied to a variety of doors and windows and other needs sealing,buffer areas.

4.The foam hardness range:20 to 80 degrees;low density:0.40~1.00g/cm3 .

5.The material properties of the implementation of GB/T 24498-2009 building windows and doors, curtain wall sealing strip.”

6.Dimensional tolerance execution”GB/T3672.1-2002 rubber tolerances-Part 1:Dimensional tolerances”.

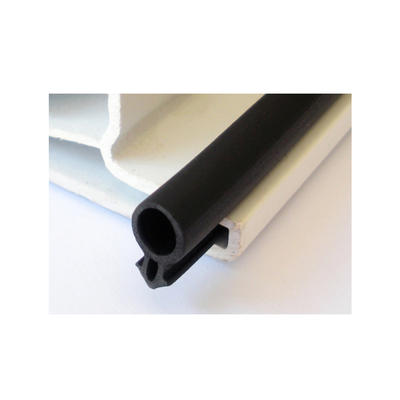

EPDM Compound Sealing Rubber Strip EP102

Name:

compound sealing strip

Item code:

ep102

Material:

epdm sponge

Application:

for window and door seal

Place of Origin:

foshan, china

Brand Name:

meirun, 3h, hehe,hehexin

Product type:

extrusion

Package:

100m/paper roll

Carton:

2 rolls/ctn

Serive temperature:

-50°c~+150°c

Certificate:

iso9001:2008 / astm

Size:

as per drawing

Hardness:

70±5

Name:

compound sealing strip

Item code:

ep102

Material:

epdm sponge

Supplier Info.

Registration Date:

2006

Country / Region:

guangdong / China

City:

foshan

Main Products:

epdm rubber seal,epdm rubber,epdm sealing strip

Product Detail

/ Product description

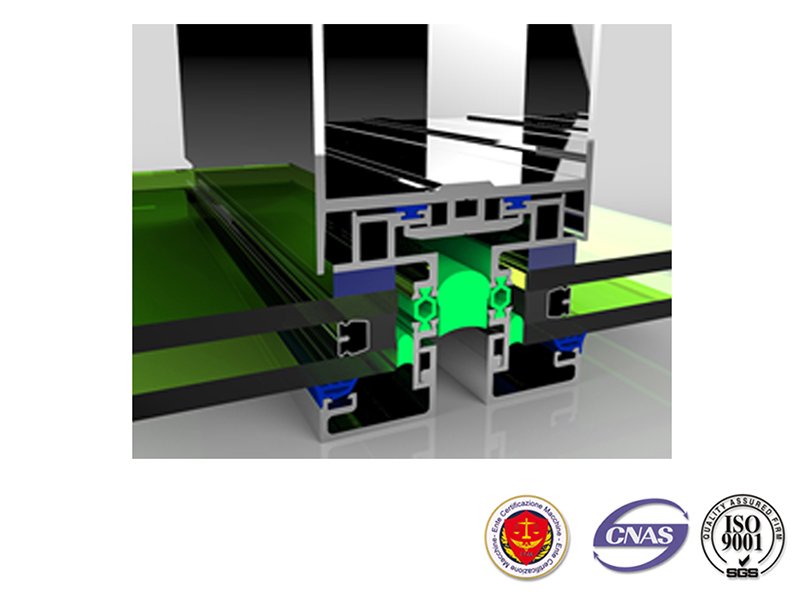

Five Sponge composite seal(EPDM) Features:

/ Car tape real picture

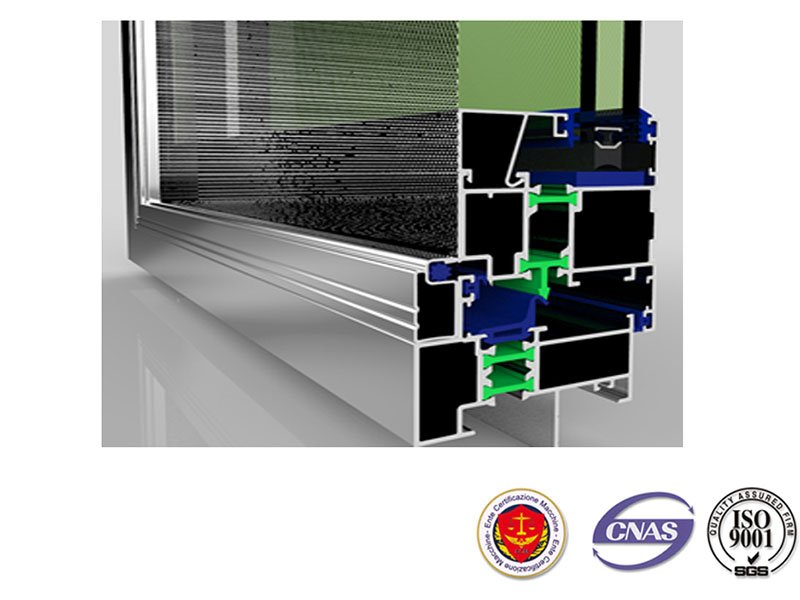

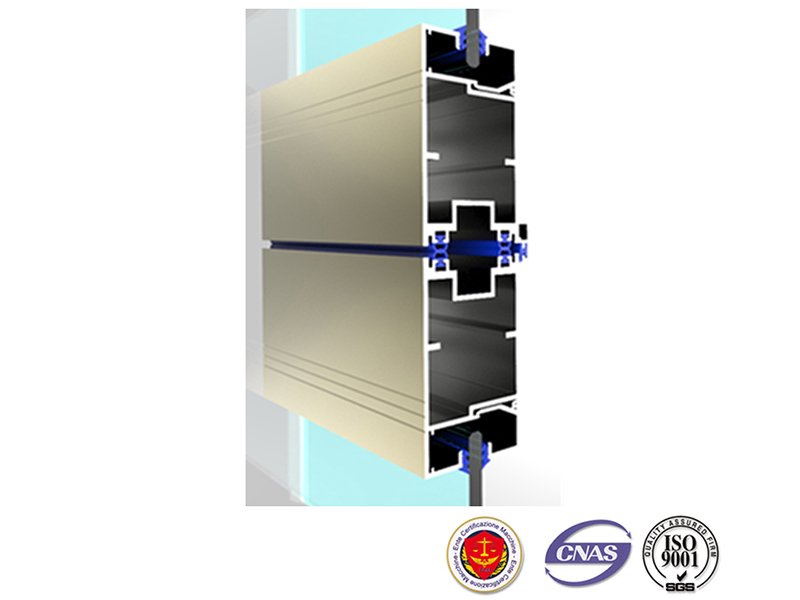

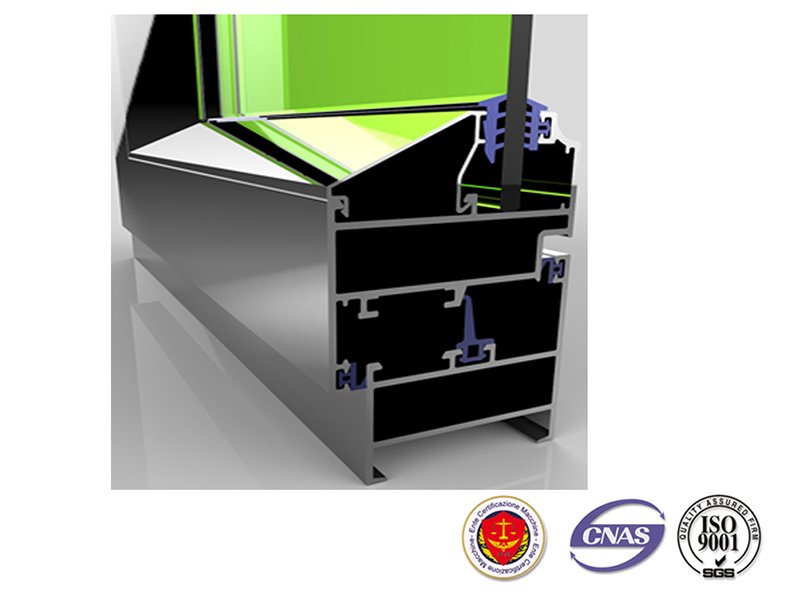

/ Product application

/ Product Material

Sealing Rubber Strip Specification

| Characteristics | EPDM Sponge | |

| Basic Characteristics | Shore A Hardness | 20±5,30±5 |

| Tensile-strength (Mpa) | ≥5.0 | |

| Tensile elongation (%) | ≥250 | |

| Compression Set (100℃*22h)(%) | ≤35 | |

| Heat Aging(100℃*72h) (Tensile-strength and Tensile Elongation Variation (%)) | — — | |

| Heat Aging(100℃*168h) (Tensile-strength and Tensile Elongation Variation(%) ) | <25,<40 | |

| Weight Loss on Heating(%) | ≤3.0 | |

| Low Temperature Brittleness(-20℃) | — — | |

| Low Temperature Brittleness(-40℃) | Pass | |

| Product Performance | Usage Temperature(℃) | -50℃~120℃ |

| Flame Retardant | N/A | |

| Ozone Proof | Excellant | |

| Storage Life(Year) | 10-15 | |

| Product Technics | Forming Method | Microwave Vulcanization |

| Corner Joint Menthods | Vulcanized | |

| Color | Black | |

/ production process

1. Mixing

Weighting-Mixing-Oping mill-Cooling

-Mixing+Opening mill

-Cooling

2.Extrusion

High-temperature setting-Micro vulcanization-Hot vulcanization-Cooling

High-temperature setting

Micro vulcanization

-Hot vulcanization(HAV1)

-Hot vulcanization(HAV2)

-Hot vulcanization(HAV3)

cooling

3.Testing

-testing

4.Packaging

-packaging

/ Product design

Contact

Supplier

Contact us

Tell us your Buying Requirements

You Might Also Like

Tigerwingspad 2018 best buy professional medium sized natural rubber custom mouse pad for ipad

Embossed Custom Colorful Pattern Shark Skin Foam Sheet 35%SCR With Prismatic Embossed Neoprene Fabric

Customized Oil Resistance Appliances Sealing Ring

plastic shower massage brush plastic shower hair brush