Fish Can Making Tooling And Spare Parts

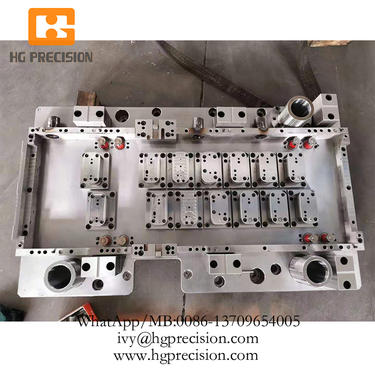

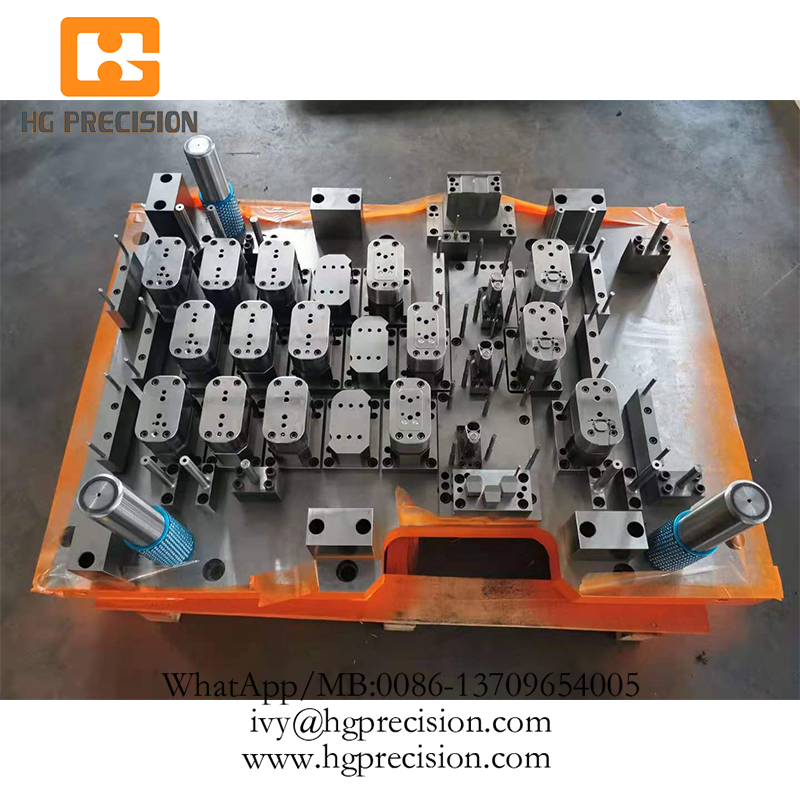

One Lane DieTooling Set For Food Can, Fish Can, Tomato Paste Can Tooling, Aluminum EOE

EOE Tooling for easy open ends. Easy peel membranes, standard ends, ring lid and taggers.

We have high accuracy Eurpean Imported machines for tooling/die punch and matrix manufacture. Furhtermore, we have Minster, AIDA, and customzied machine for tooling trial.

Not only tooling manufacture, the machine process will be by rich experience engineers to design and make for you. Not only sheet cutters, automatic EOE post repair and dryers, and scroll dies, score depth testers and torque testers.

Design& Manufacture: professional

Tooling Manufacture leadtime: 40-150days

Material: Tungsten carbide, high speed steel and other high precision material

High Top Accuracy Equipment:

EDM: agie Charmmilles CUT20P, CUT2030 and Agietron Hyperspark2

Machine Center: Mikron HSM400, VCP600 and HSM700

Grinding: Moore Jig Grinding 450P, Nicco NFG515, Kuroda GS-BMHF

CNC Lathes: Okuma L270;

QC: Zeiss Eclipse550, Eassen EV-4030

We continue to invest in new equipment and technologies that allow to deliver superior, cost-effective precision solutions.

The HG Precision EOE Tooling can make the sizes are:

Tin palte and TFS easy open ends

Round size: 200, 202, 209, 211, 300, 307, 401, 404, 502, 603

Irregualr Shape: 304, 311, 312, 313, 316, 812, 501, 601, 604

Aluminum EOE’s: beverage/pour opening:

200RPT, 202RPT, 202SOT, 206SOT, 206SOT. 209RPT, 209RPT, 300RPT

Full/Partial Opening: 211 full open, 211 partial open, 300 full open, 307 full open, 401 full open, 401 partial, 502 full open, 603 full open.

Different internal and external lacquers available

Wide range of lacquers to cover all market needs: will lacquer, aluminised lacquer, meat relase lacquer, gold organosol lacquer

Easy Pell membranes:

Sizes available: 300, 307, 401, 502, 603, 710

Normal ends for tin and composite cans

Sizes ranges from 500mm to 153mm

Ring lid and taggers/penny lever:

Sizes available are 73mm, 99mm, 108mm, 127mm, 153mm

Mold Trial:

We have Minster/Aida, kinds of press machine for your tooling trial.

The quality of your aftermarket parts matters. By working with HG Precision, you can be assured that your parts work the “first time, every time.

Customers can order spare parts for their container end systems by mail: ivy@hg-jingmi.com. To aid in part identification, an on-line bill-of-material may be available.

Contact

Supplier