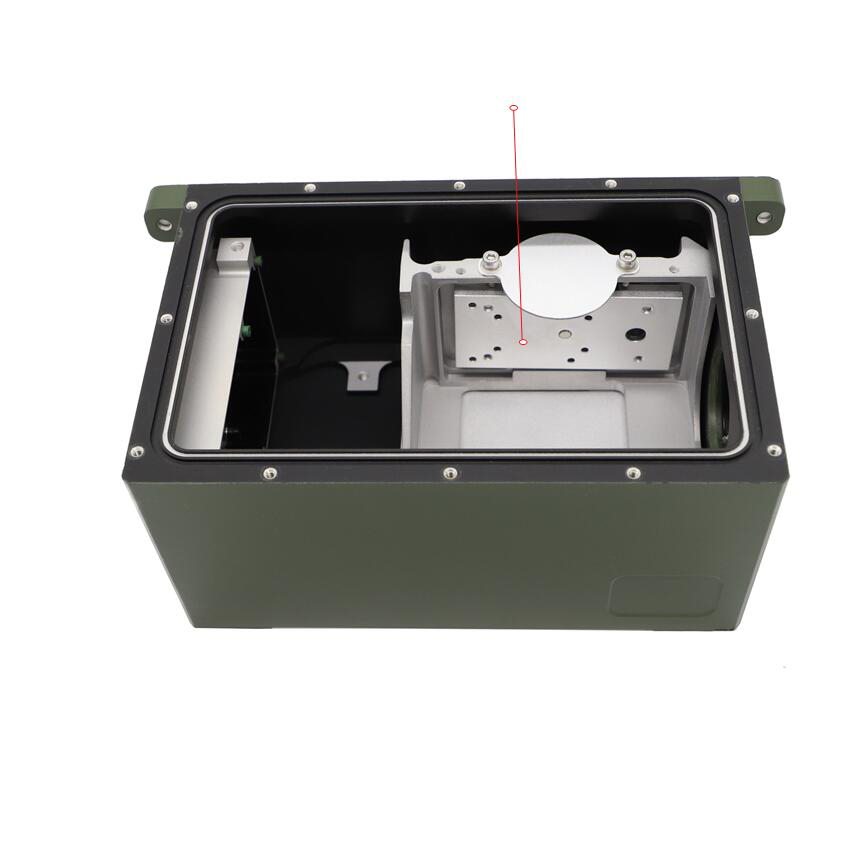

High Precision CNC Machining Aluminum bracket Parts for camera

High Precision CNC Machining Aluminum bracket Parts for camera

Xavier providing cnc machining aluminum parts for camera, the accuracy is 0.01mm and hole accuracy 0.08mm. The accuracy affect level adjustment. Parallelism, flatness affects the level and affects aiming.

Surface treatment:

Hard anodic oxidation+SurTec 650. Hard anodizing produces a hard wear and an abrasion-resistant coating of aluminum oxide on the surface of aluminum alloys. The purpose of hard anodizing of aluminum is to increase hardness and wear resistance of this part. SurTec 650 is suitable for alloyed and casted aluminium and pretreatment before laquering, powder coating and gluing. It is easy to handle in immersion, spray and wipe application and produces an iridescent, faintly blue to tan and visible layer.

Application:

It was used for the near-infrared imaging system, fire control systems, target acquisition, recognition systems. Xavier have experience in the exacting areas of aerospace and the defence industry and are one of the leading manufacturers of custom cnc parts and assemblies.

Need help with our cnc machining service? Contact us today for more info.

Contact

Supplier