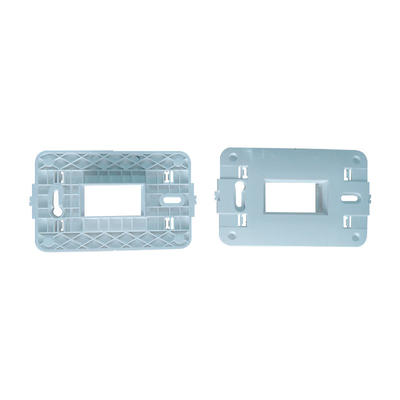

Intake manifold for the Peugeot Citroen by injection mould

This a intake manifold of automobile. It is made of the material PA66+25%. It is a engineering material. It works in high temperature environment. The product size is 17x86x53mm. In general, the wall thickness of the product is 2.5mm. The product is arc shape. One side is big, another is small. The big side has a thread for connecting. The small side has a hook for connecting. There is small connecting pipe in the middle of the product. This is a three-way pipe.

A single cavity mold is designed for this product. Hot runner system is used in the mold. The gate type is valve gate. There is no cold runner in this mold. The mold structure is very complex. There are three sliders in the mold. The slider of the big side has a long stroke (is 165mm). And it moves along a arc rail. It mainly forms the inside of the product. So it needs a good cooling loop to cool it. There a slider for the small side. Also it needs a cooling loop to cool it. There is a fixing mechanism between two sliders. The function of the fixing mechanism is to avoiding the sliders moving of when injecting.

There is a slider to form the inside of the connecting pipe. The lines of the slider must be good because the connectors of the product have a sealing requirement. The step of the parting line is max 0.03mm. No flash is allowed at the parting surface. There are some marks with index number, part number and date stamps in the cavities side. The date stamp includes month and year. The cooling system is supplied with hot water because the mold temperature requires 65-93°C. The product is ejected out by round ejector pins after injecting.

We have rich experience on this type mold. And we did enough preparation and technical analysis before mold design. The mold was delivered to customer in advance. The customer was very satisfied with our work and mold quality.

Contact

Supplier