Semi-automatic Coagulation Analyzer for Maccura

| Product Name: | Semi-automatic Coagulation Analyzer |

| Product size: | 228*219*57mm |

| Part visible surface: | Texturing |

| Product material: | PC+ABS |

| Shrinkage rate %: | 0.6 |

| Cavity quantity: | 1*1 |

| Injection machine type: | 200T |

| Cycle time: | 36S |

| Product Take out way: | Manipulator/Cupula |

| Cooling system: | cold runner |

| Cavity and core steel: | 718H |

| Mold base standard: | LKM |

| Terminal Customer: | Maccura |

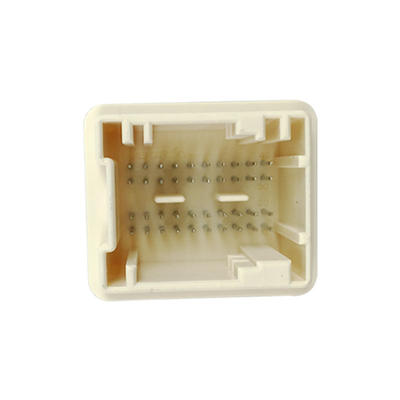

In this set of products, the surface shell mold can adopt large nozzle mold or hot nozzle to cool the flow channel mold, which can not only meet customer requirements but also reduce the cost of the mold;

Among them, the way of glue injection is diving, but the glue inlet is different from the common conical shape but similar to duck mouth shape, which can reduce the pressure of glue injection and prevent shrinkage lines.

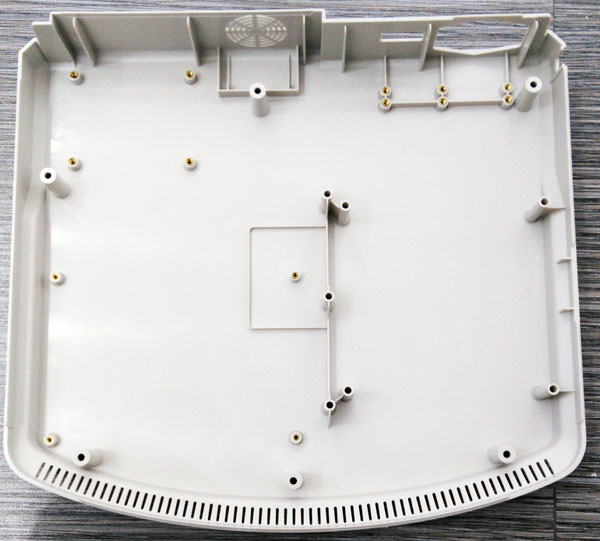

The back shell mold is fine nozzle mold or single hot nozzle mold can meet the customer requirements.

In the mold processing, the front mold processing is very important, the front mold surface can meet, relatively flat, in the design of the front mold as far as possible to make the prominent part of the front mold insert, in order to facilitate the shape of the small R Angle can be directly processed by 3 axis or 5 axis machining center molding, if you can't do it, you should do the whole graphite electrode Electric Discharge Machining molding.

Contact

Supplier