IRB 2600ID TIG / MIG / Pinch Welder Industrial Welding Robots

| Main Application | |||

| Machine tending, material handling, arc welding | |||

| Specification | |||

| Variants | Reach | Payload | Armload |

| IRB 2600ID-15/1.85 | 1.85 m | 15 kg | 10 kg |

| IRB 2600ID-8/2.00 | 2.00 m | 8 kg | 15 kg |

| Number of axes | 6 | ||

| Protection | Standard IP67 for base and lower arm.IP54 for upper arm. | ||

| Mounting | Floor, wall, shelf, tilted, inverted | ||

| IRC5 controller variants | Single cabinet, Dual cabinet | ||

| Physical | |||

| Robot base size | 676 x 511 mm | ||

| Robot height | 1600 mm | ||

| Robot weight | 273 to 276 kg | ||

| Performance (according to ISO 9283) | |||

| Position repeatability (RP) | 0.023 - 0.026 mm | ||

| Path repeatability (RT) | 0.27 - 0.30 mm | ||

| Movement | |||

| Axis movement | Working range | Maximum speed | |

| Axis 1 | +180° to -180° | 175°/s | |

| Axis 2 | +155° to - 95° | 175°/s | |

| Axis 3 | +75° to - 180° | 175°/s | |

| Axis 4 | +175° to - 175° | 360°/s | |

| Axis 5 | +120° to -120° | 360°/s | |

| Axis 6 | +400° to - 400° | 500°/s | |

| Electrical Connections | |||

| Supply voltage | 200-600 V, 50-60 Hz | ||

| Environment | |||

| Ambient temperature for mechanical unit | |||

| During operation | + 5°C (41°F) to + 45°C (113°F) | ||

| During transportation and storage | - 25°C (- 13°F) to + 55°C (131°F) | ||

| For short periods (max 24h) | up to + 70°C (158°F) | ||

| Relative humidity | Max. 95% | ||

| Safety | Double circuits with supervisions,emergency stops and safety functions,3-position enable device | ||

| Emission | EMC/EMI shielded | ||

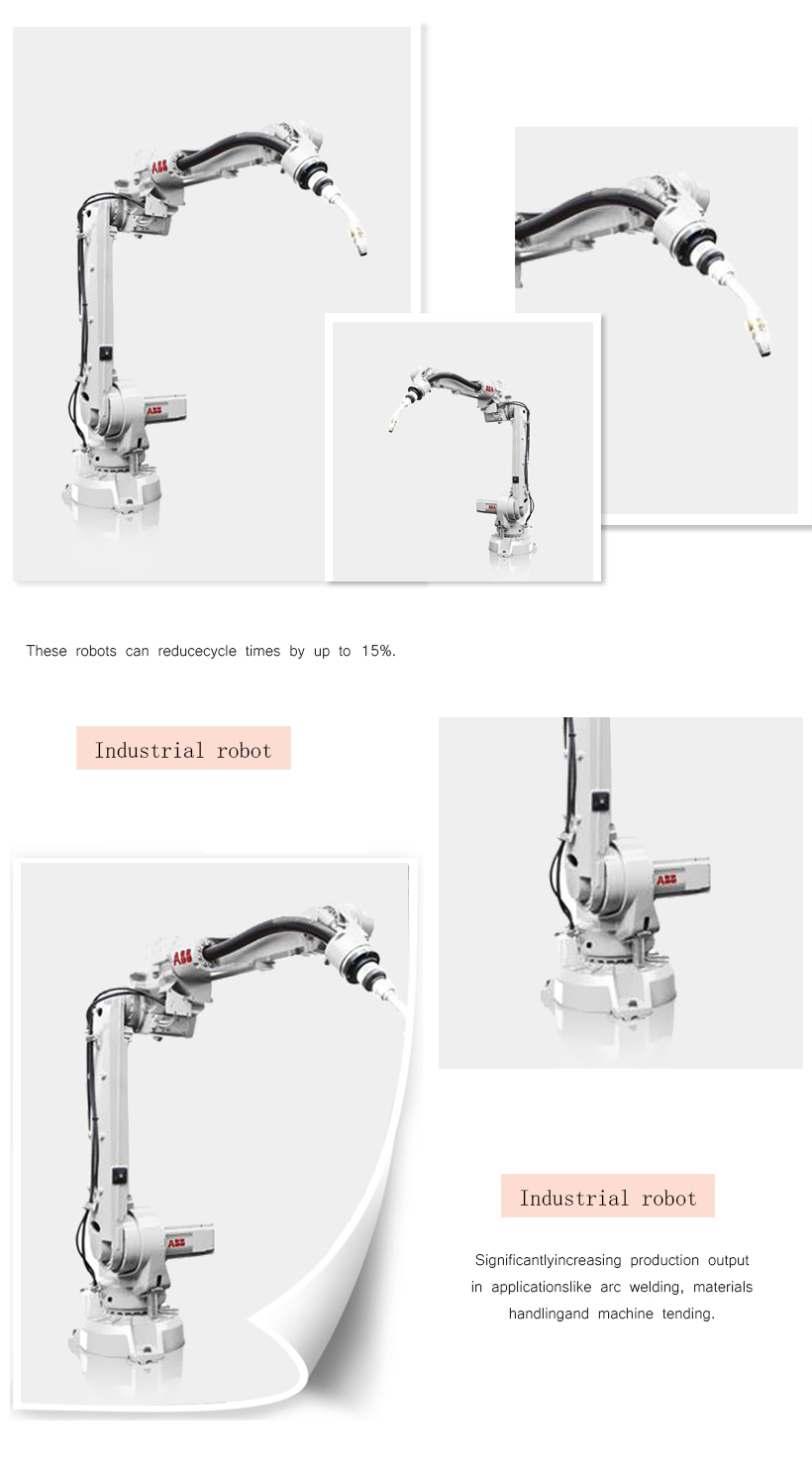

The IRB 2600ID industrial robot delivers higher output from a smaller footprint in Arc Welding, Materials Handling & Machine Tending applications.

Thanks to the Integrated Dressing (ID) technology and the larger working envelope, cycle times can be reduce by up to 15% and cost of ownership reduced by 75%. There are two versions available: 15kg with 1.85m reach and 8kg with 2.0m reach.

With the IRB 2600ID cycle times are significantly reduced and reliability increased. With all cables and hoses firmly secured, movements are easily predicted making off-line programming and simulations perfect representations of the actual robot system. Programming is faster and more reliable. And with less swing of cables, the robot can run at maximum achievable acceleration at all times.

Lifetime of hoses and cables increases significantly. Being secured and protected, they swing less during operation, and are less exposed to weld spatter or cutting fluids,

With its compact design and without loose hoses and cables, the IRB 2600ID has a very small footprint allowing for productive, high-density installations with 50% more robots, and up to 50% higher output from a production cell.

With a slim wrist and integrated dressing IRB 2600ID can easily access narrow openings and perform complex movements.

For example, in arc welding this means that the IRB 2600ID can do circular welds without interruption and without compromising quality – and in a much shorter cycle time.

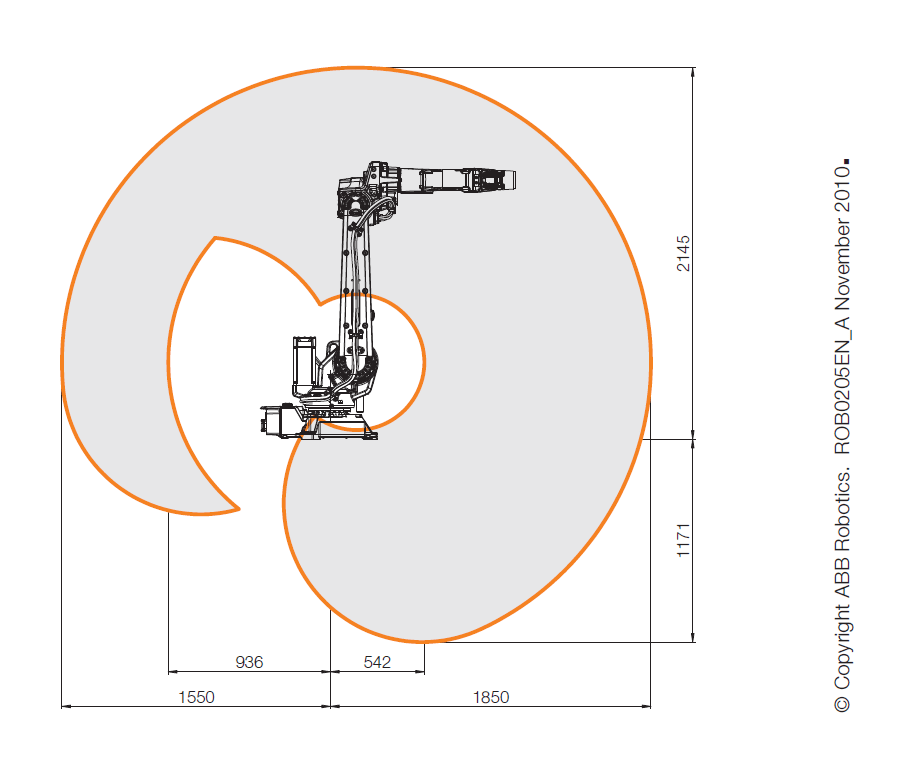

IRB 2600ID-15/1.85

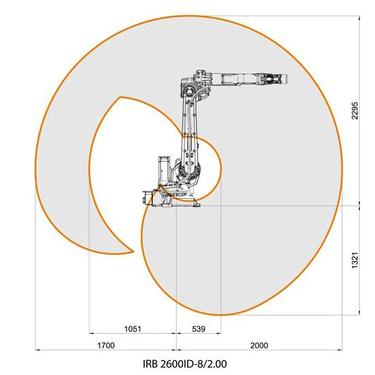

IRB 2600ID-8/2.00

The IRB 2600ID robot range features a

unique combination of high payload capacity.

[large working range and Integrated

Dressing (ID), which routes all cables

and hoses inside the robot’s upper arm

and wrist. ]

Shorter cycle times

Because all process cables and hoses are routed inside therobot arm, the IRB 2600ID robots dramatically decrease

downtime caused by interference and wear. This integrationalso ensures that the maximum achievable acceleration is

available at all times without restriction. These features help to significantly reduce total cycle times and increase reliability.

There are two models in the range. The 2.00 m reach, 8 kgversion is designed to be integrated with arc welding processequipment. The 1.85 m reach, 15 kg model comes with aflexible conduit designed to optimise materials handling andmachine tending applications.

Faster programming

The ease with which off-line programs can be created isenhanced with Integrated Dressing (ID). The controlled movements of the hoses and cables are easily predicted, soprogramming and simulations are perfect representations ofthe actual robot system. This minimizes the time required forfine-tuning programs and enables a faster start of production.Total programming time is reduced by up to 90%.

Reduced cost of ownership

With all hoses and cables firmly secured and protected, theyswing less during operation, and with less exposure to weldspatter or cutting fluids, the lifetime increases significantly.Costs are reduced in terms of purchasing and exchange byup to 75% and up to three production stops per year can beeliminated.

Higher output from a smaller footprint

With its compact design and without loose hoses and cables,the IRB 2600ID has a very small footprint with a swing baseradius of only 337 mm and a base width of only 511 mm. Inmaterial handling and machine tending, this means that therobot can be placed closer to the machines being served. Inarc welding the reduced risk of interference with other robotsallows for productive, high-density installations with 50%more robots, and up to 50% higher output from a production cell. That’s how the IRB 2600ID helps you make the most outof your production space; higher output from a smaller area.

Increased agility in smaller spaces

The wrist is very slim, only 227 x 130 mm. With all hoses andcables integrated through the process wrist the robot caneasily access narrow openings and perform complex movements.For example, in arc welding this means that the IRB2600ID can do circular welds without interruption and withoutcompromising quality – and in a much shorter cycle timethereby increasing production output.

Contact

Supplier