KF94 Fished Design Mask Machine Full-Automatic

1.Application scope:

For manufacturing the Korea KF94 and Japan DS2 masks.

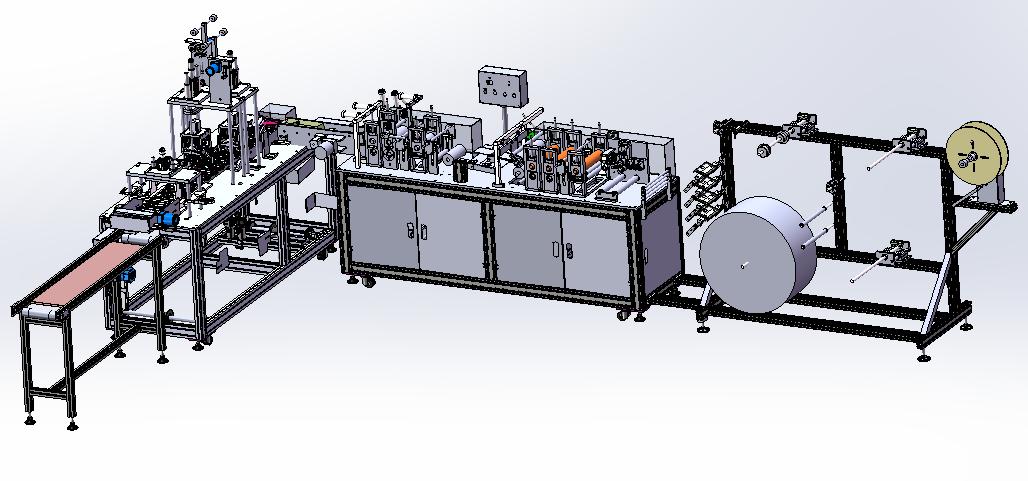

2.Produce Drawing:

3.Product Specification:

Applicable folding mask product size | Foldable masks with market size |

Material width | According to the product size |

Production capacity | 40±5pcs/minute |

Suitable power supply | 220V/380V,50HZ/60HZ |

Applicable air supply | 0.5∽0.7Mpa |

rated power | 7.5kw |

Machine size | 5700mm x 4500mm x 1900mm |

Machine weight | Weighted by section, single section is less than 200KG |

4.Product Features:

The whole machine is composed of the material rack part, the upper nose line part, the shape welding part, the folding forming, the shape cutter part, the turning part, the material dividing part, the ear strap part, and the collecting part. .

4.1. Material frame part: air expansion shaft, magnetic powder brake and controller to ensure that the material tension is not wrinkle.

4.2. Upper nose line part: the cylinder is welded with ultrasonic wave to fix the nose line with required length to the material.

4.3. Shape welding part: the mold is matched with ultrasonic wave, and the initial texture welding.

4.4. Folding: folding fabric

4.5. Shape cutter part: custom-made cutter, roll-cut forming, at this time the mask is initially formed

4.6. Flip part: turn the mask over to prepare for ear straps

4.7. Partitioning: Reasonable distribution, increased production capacity

4.8. Ear strap part: a special rotating disk for the mask machine industry, which is used to spot weld the ear strap line on the semi-finished mask with ultrasonic, and the mask is formed at this time

4.9. Collection part: take out the belt, product collection

![]()

5.Attention Tips:

5.Attention Tips:

5.1. The warranty period of our products is one year.

5.2. Attentions should be paid when handling the machine: it is best to use a forklift or crane for handling. The bottom of the machine should be supported when using a forklift or crane. (Caution: Do not press on the cable). When carrying on flat ground, it can be carried by manual hydraulic truck or directly pushed by the caster of the machine. In order to prevent the four casters on the bottom of the machine from being stressed for a long time, after the machine is moved to the designated position, the four feet on the bottom of the machine should be supported by the machine.

5.3. When turning on the power, check whether the main power line is correct.

5.4. Before the adjustment, installation and adjustment of each part, the power switch must be turned off, or the safety switch must be pressed to confirm and implement it to ensure the safety of the operator and the equipment.

5.5. After adjusting each part, the screws and nuts must be locked to avoid loosening, which can ensure the stability of the printing effect and extend the reliability and life of the mechanical equipment.

5.6. In case of emergency or abnormal situation, immediately press the safety switch, the machine will stop running to maintain the safety of the operator or protect the equipment from damage.

7. The adjustable screw parts on the machine table are kept lubricated with mechanical oil.

8. Please add lubricating oil to the moving parts of the machine regularly.

6.Machine Maintenance:

6.1. The production workshop using the machine should be kept neat and clean.

6.2. The appearance of the machine should be kept neat and clean, requiring frequent scrubbing.

6.3. The sliding parts of the machine should always be filled with pollution-free lubricants.

6.4. When not using the machine for a long time, cover the machine to prevent dust.

6.5. When the machine is not used for a long time, the input power of the machine should be cut off.

6.6. When the machine is not used for a long time, the rusty part of the machine should be coated with protective oil.

7.Installation and training

7.1. Unless otherwise required in writing, the acquirer is responsible for receiving, unpacking, and transporting the unit to the installation site; and preparing related electricity and gas to the installation site.

7.2. The supplier is responsible for equipment installation, commissioning and system integration.

7.3. After the installation is complete, the two parties will conduct small-scale trial production of their equipment, and the small-scale trial production will be qualified and approved by the purchaser before being put into formal mass production.

7.4. The supplier provides free training for the relevant personnel on the demand side. The content includes the normal use of the equipment, maintenance, fault analysis and troubleshooting, operation safety and emergency procedures.

7.5. Due to the impact of the epidemic, products exported to foreign countries will only provide English mail support;

7.6. We have recorded some video tutorials with English letters for foreign customers. If you need, please email to contact us.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts