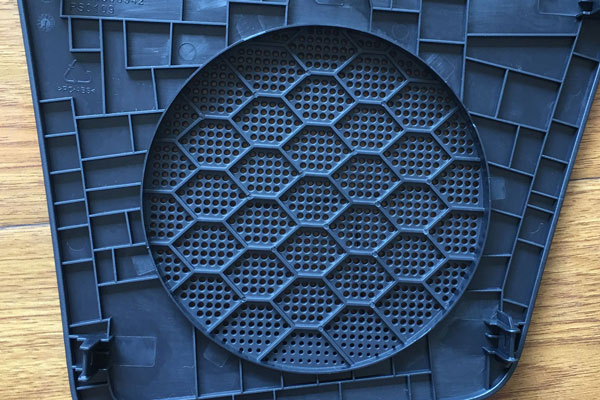

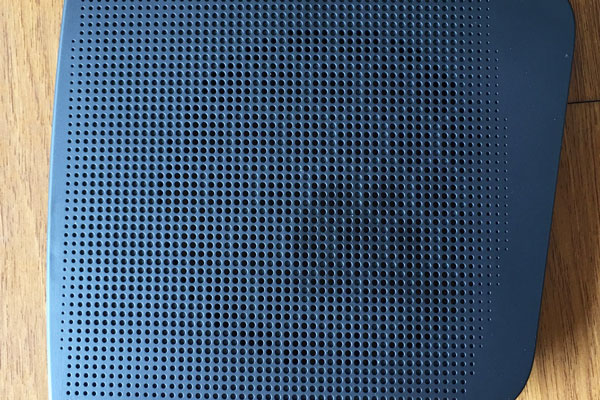

Loudspeaker part for the QIANTU car stereo of the speaker parts

This is a loudspeaker cover, which is used in QianTu car. The material is PC+ABS. The size of the part is 217*206*30mm. There are many small holes and thin ribs on the part. There are two stamps with month and years. The marks are recycle and name of plastic material. And five hooks are used to fix on the frame of loudspeaker. The finish is grain (VDI 3400 ref 30) on viewable surface and polished on the inner surface. No flash、injection gate、ejector mark and fault are allowed on the viewable surface. To produce the part, it need a injection mold with good venting and good finish.

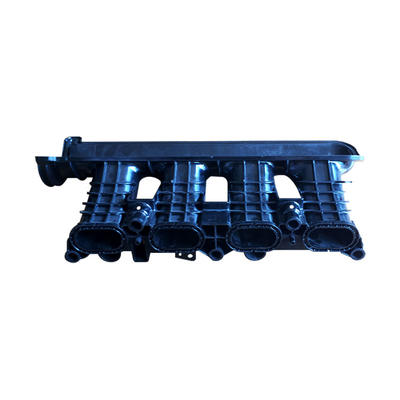

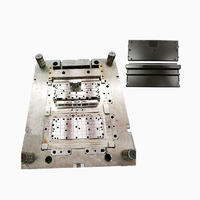

A mold with one cavity and hot runner system was built to produce the part. Five angular lifters were designed to form the hooks. The mold was cooled by cooling water. The cycle time was about 39 seconds. The part was ejector out by round ejecting pins. For the mold, the most important was to manufacture the area with small holes and the thin ribs. Core insert can't be milled by CNC and polished because there were too compact small holes and thin ribs.

So it needed to make graphite electrode to do EDM. The finish of the surface is 4u-6u Rmax.In this way, the part can demould smoothly without polished. To get good surface of the electorde, it was very import to choice the graphite grade. The graphite must be high strength and fine particles. The size of the particles was about 1-5μm. Too many holes had an effect on flowing of the plastic material when injecting. It was easy to cause venting issue.

So it needed a good venting system in the mold. So that some venting inserts were designed in the core side of the mold. To get the viewable surface with EDM texture VDI 3400 ref30, a big copper electrode was made to do EDM. It was a high precision electrode. Also it was done in a good EDM machine. To make lifters moving smoothly, the holes of the lifters were made by slow wire cutting. And a copper guide block was designed for the lifter.

Contact

Supplier