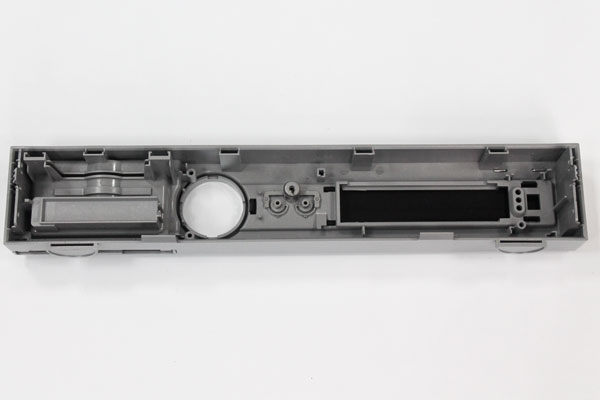

STB of electronicmmunication product

We set sprue bushing on round opening,when fill with sub gate from both sides.Ejector sleeve need locate on boss to help release part.Pin or insert for high side rib to help air venting,also for easily manufacture or EMD process.A slider would be need for side undercut.Since all outside surface are visible,no slider split line is allowed.This mean a tunnel slider would be needed on core side.Mold base size would be 600X400mm with height 350mm.The design of the mold provide for simultaneous opening of the two parting lines with the aid of two racks and a pinion for each side.As it is essential that no gate marks show on the front of the molded parts,injection had to take place on the inside.

This cover transfer heat quickly to mold surfaces.so that increased outlay on the cooling system is worthwhile in molds for such parts.Cooling of the core should be given special attention.Also some of the inserts are thin and very high.A beryllium/copper cap with six radial cooing channels is placed on the core insert.These cooling channel require drilling of the center of rube leading to the cap.This drilling weakens the center tube and there is the risk of rupture if the mounting nuts are tightened excessively.Compression spring are provided to permit an exactly defined tightening torque.Coolant is supplied to the cooling channels in the slides via tubes threaded into the slides.Slots in the guide strips allow these tubes to follow the motion of the slides.

Contact

Supplier