MIDDLE-SCALE NANOFIBER PRODUCTION LINE MF05-001

Public information shows that melt-blown material has 25g and 50g, filtration efficiency has 90%, 95% and 99% and other several level, is usually referred to as 90%, 95% and 99%, respectively on behalf of 90%, 95% and 99% of the non-oily particles. Current EU standards require melt-blown at 95L/min flow conditions under the test, the filtration efficiency should be more than 94%. From this point of view, PFE less than 90% melt-blown cloth has not met the export standard requirements of masks.

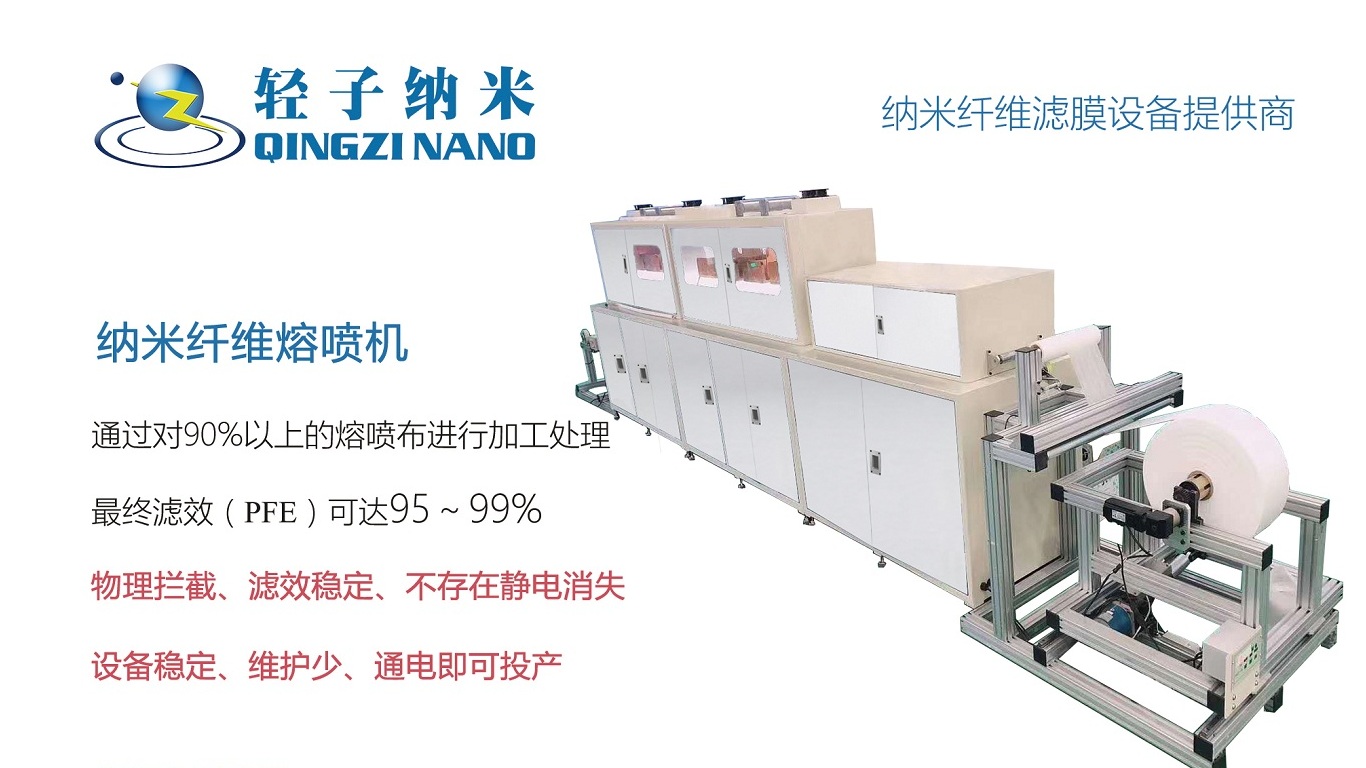

Qingzi Nano "nanofiber melt-blown machine", through the processing of the filtering effect 90% melt-blown cloth, the final filtering effect (PFE) can reach 95~99%!

When the filter effect is less than 90%, the melt-blown cloth can increase the profit many times after the equipment processing reaches level 95 and 99.

◆ Technical Advantages

Pure physical interception, no static decay, stable filtering effect.

Stable equipment, less maintenance, once the power is on, it can be produced immediately.

◆ Equipment Introduction

Model: MF05-001

Final filtration efficiency (PFE) after processing: 95~99%;

Delivery date: 10-15 days;

Equipment composition: spinning module + winding module + electric control module + liquid supply module

Floor area: 7.5m (l) *1m (w) *1.6m (h)

Equipment power: 7.5KW

Production workers: one person can operate the equipment, the operation and maintenance is simple, no experience, education, basic

requirements for production personnel

Width: 300 mm

Production speed: 10~15m/min;

| Recommended production rate (m/min) | Width of the substrate (mm) | Daily Working hours (HR) | Daily output length (m) | Daily output area (㎡) | Reference output (KG) | The raw material cost of processing one ton of melt-blown cloth |

| 10-15 | 175 | 20 | 12000 | 2100 | 70 | 879~1465 USD |

| 10-15 | 260 | 20 | 12000 | 3120 | 100 | 879~1465 USD |

Parameters:

Integrated design of winding, unwinding, and drying;

Precision feeding system: corrosion resistance, high-voltage resistance;

Safeguard system;

Technical electrospinning multi-nozzle array system;

Speed of roll-to-roll: 0-5 m/min, adjustable;

Electrospinning high-voltage supply: 0-50 kV, adjustable;

The effective width of the nanofiber layer: 300 mm.

Electrospinning technology: electrically charged polymer solution or melt is stretched and refined in a high-voltage electrostatic field, accompanied by solvent volatilization or melt solidification, and becomes micro-nano-level fiber, which is deposited on the receiving device to form nanofiber film material with a certain accumulation density.

Features of electrospinning materials: High porosity; Small aperture; High specific surface area.

Application: air filtration, water filtration, battery diaphragm, electrode material, tissue engineering, drug sustained release, drug delivery, dressings, artificial skin, heavy metal ion adsorption, gas sensor, waterproof and moisture permeable clothing, catalyst, reinforcement, etc.

Polluted waste treatment: heavy metal ion adsorption, acid-base treatment, organic waste gas treatment, organic wastewater treatment, small molecule pollutant adsorption, etc.;

Filtering separation: suspension particles, PM2.5 mask, air filtration, water filter, sifting, oil-water separation, extraction, seawater desalination, etc.;

Biological medicine: air-filtration, drug delivery, dressing, drug extract, tissue engineering scaffold, biological testing, cosmetics, anti-microbial, artificial organ, enzyme immobilization, etc.;

New energy: organic solar cells, li-ion electrode material, sodium-ion battery material, fuel cell, li-ion battery separator, photocatalytic hydrolysis, etc.;

Electronic information: gas sensors, humidity sensors bioinstrumentation, flexible circuit, microfluidic chip, micro/nanodevice, etc.;

Catalysis: organic wastewater and gas catalytic treatment, photocatalysis, chemocatalysis, etc.;

Defense industry: missile insulation, stealth wave-absorbing, light isolated material, electromagnetic shielding, etc.;

Other: food processing, composite enhancing, antiseptic, waterproof and moisture permeable, aerogel, high temperature insulating, keeping warm, etc.

Common Electrospinning Materials

1. Water solubility

PEO polyoxyethylene

PVA polyvinyl alcohol

PVP polyvinylpyrrolidone

2. Water-insoluble

PVDF polyvinylidene fluoride

PAN polyacrylonitrile

PU polyurethane

PA Nylon, polyamide

PS polystyrene

PC polycarbonate

CA cellulose acetate

PMMA polymethyl methacrylate

PET Polyethylene terephthalate

3. Biocompatibility

PCL polycaprolactone

PLA polylactic acid

CS chitosan

SA Sodium Alginate

SF silk fibroin

HA hyaluronic acid

Qingzi Nano has designed three solutions for the air filtration industry combined with our nanofiber mass production equipment.

1. Nano antibacterial membrane, antibacterial efficiency up to 99.99%. It can be added to the vehicle-mounted filter screen, filter element, air filter, and HEPA to filter bacteria in the air.

2. Add a layer of nanofiber film to melt-blown cloth, hot air cotton, etc. to improve the filtration efficiency, which can reach PFE 95-99% stably, the filtration efficiency will not reduce, and the service life will be longer.

3. Spin a layer of nanofilm on a spunbonded cloth to make a pure nanofilm with high filtration efficiency and low wind resistance. Monolayer nanofilm PFE 65-85% with the resistance of 17-25 Pa. It can be used in a window screen, air purifier, and other products.

Air Filtration

Although the traditional fiber air filtration materials can effectively intercept the micron solid particles, the filtration efficiency of the submicron solid particles is low. Nanofibers have the characteristics of small diameter and large specific surface area, which can further enhance the interception of suspended particles. By electrospinning technology system of the preparation of nanometer fiber membrane with good fiber uniformity, controllable pore size distribution, the characteristics of the structure can be adjusted, according to the actual use of the environment demand to choose different polymer materials, which could be prepared for the different particle size of solid particles of high-efficiency low resistance air filtration material, do the special environment of application scenarios have larger development prospects.

High-Temperature Filtration

PM2.5 Masks

High-Efficiency Cartridge Filter

Haze Screening

HEPA Filter

Air Conditioning Filter

Application of Nanofiber Membrane Masks

The production principle of the nanofiber air filter is different from that of melt-blown cloth. Contrast melt-blown fabric with air drawing process, nanofiber air filter material using electrostatic wiredrawing, the fiber is finer, and the new product upstream materials will not be limited to polypropylene, as long as it is able to dissolve in the solvent of polymers, including polyurethane, eps olefins, polystyrene, etc. It can be used for textile, much lower production cost than traditional melt-blown cloth. Nanofiber membrane adopts advanced electrospinning nanofiber technology, and the pore diameter of the nanofiber membrane is about 100~500nm. Compared with the fiber prepared by the melt-blown process, the pore diameter is smaller and the antibacterial property is better. It effectively blocks filtering dust and PM2.5 particles with filtration efficiency up to 99.99% and effectively inhibits more than 650 bacterial viruses such as the influenza virus, MERS, SARS, and bacteria.

A. Nanofiber membrane replaces melt-blown cloth as the core filter layer of masks, with the following advantages:

1) The resistance, BFE, PFE, etc. are superior to the melt-blown cloth.

2) Instead of relying on electrostatic adsorption, physical interception is adopted, relying on the principle of physical pore filtration, that is, finer 'mesh' is used to achieve filtration effect.No static electret treatment is required, longer protection effect, no static disappears.

B. Nanofiber film melt-blown composite

1) Melt-blown cloth composite nanofiber processing, easily on 95+, stable 95+, to solve the export problem, easily oily, salt test!

2) Through equipment processing up to 95, 99, solve the problem of low filtration efficiency melt-blown inventory backlog, effective use of existing resources, and can increase the profit of many times! (At present, the price of low-quality melt-blown cloth on the market falls to about 1,465 USD. After processing the melt-blown cloth with the Qingzi Nano production line, it can be sold directly according to 95+ and 99+ melt-blown cloth, and there is no static electricity to disappear. Customers do not need to worry about the product being randomly inspected and disqualified after export.)

3) The processing cost of one ton of melt-blown cloth is the only US $879~ US $1465!

Winnie Chan

International Trade Manager

Mob./Whatsapp: +86 18520902852

QQ: 1130008454

WeChat: QingziNano

E-mail: winnie@qingzitech.com

Tel.:+86 757-89956076

Web. : https://www.qingzitech.net/

Facebook: https://www.facebook.com/LeptonChina/

Twitter: https://twitter.com/?lang=zh-cn

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts