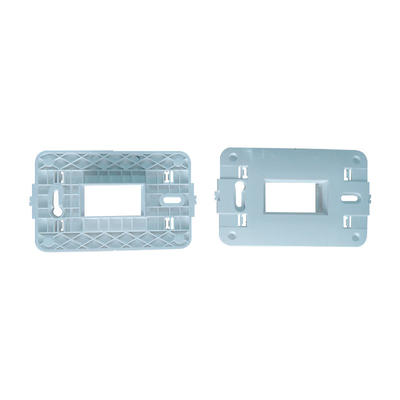

Monitoring shell for Siemens

| Product Name: | monitoring shell |

| Product size: | 607*559*461mm |

| Part visible surface: | Texturing |

| Product material: | PC+ABS |

| Shrinkage rate %: | 0.6 |

| Cavity quantity: | 1*1 |

| Injection machine type: | 500T |

| Cycle time: | 45S |

| Product Take out way: | Manipulator/Cupula |

| Cooling system: | cold runner |

| Cavity and core steel: | 718H |

| Mold base standard: | HASCO |

| Terminal Customer: | Siemens |

| Export: | Germany |

In this set of products, the surface shell mold can adopt large nozzle mold or hot nozzle to cool the flow channel mold, which can not only meet customer requirements but also reduce the cost of the mold;

Among them, the way of glue injection is diving, but the glue inlet is different from the common conical shape but similar to duck mouth shape, which can reduce the pressure of glue injection and prevent shrinkage lines.

This product made in ABS+PC material, which can improve the heat resistance, impact resistance and tensile properties of ABS and enable ABS to be used in high-end fields.

On the other hand, it can reduce the melt viscosity of PC, improve the fluidity of PC, improve its processing performance, reduce the internal stress of products, reduce the sensitivity of impact strength to gap and thickness, so that PC can be used for the manufacture of thin-wall long process products.

Since the front mold of this product has bone position and screw column, in order to prevent adhesion of the front mold, the slider can be used in the middle part of the product to force the rear mold.

In the aspect of medical product assembly, it is best to be supplemented by hot-melt method, or adopt the method of fastening seal and front shell as a whole to strengthen the degree and increase the tightness. All external interfaces shall be protected and sealed by rubber protective cover to prevent internal pollution of the product.

Contact

Supplier