PVC 4 outlet pipe extrusion line

Quick Details

Condition: New

Application: Pipe

Plastic Processed: PVC

Screw Design: Double-screw

Automatic Grade: Automatic

Place of Origin: Guangdong, China (Mainland)

Brand Name: Yige

Model Number: SJZ65/132

Voltage: Customized

After-sales Service Provided: Engineers available to service machinery overseas

Warranty: 1 year

MOQ: 1

Customized: YES

Features

1. Due to the conical screw feature, the feeding section screw has a larger diameter, increasing heat transfer areas and material shearing speeds of materials and making material plasticization easy; the metering section screw has a smaller screw, reducing the heat transfer areas of materials and the shearing speeds of melts and enabling melts to be extruded at lower temperatures.

2. A quantitative feeding device is provided, making the extrusion capacity match with the feeding capacity and ensuring steady extrusion of products.

3. Interior of the magnetic body should be provided with a magnetic body to avoid entry of ferreous foreign matters and protect the screws.

4. The screws are conical. Their smaller ends are metering sections with smaller sectional areas and axial forces and their larger ends have larger space and can be installed with bearings that can withstand larger axial loads.

5. A distribution gearbox is provided. The driving torque is evenly distributed to each screw through it.

6. The barrel is heated by a cast aluminum electric heater that has a long life and can be dismantled and assembled conveniently.

7. The barrel is subject to strong air cooling that has a small temperature fluctuation.

8. An AC variable-frequency speed regulating device is provided to make the main motor realize convenient stepless speed regulation and steady speed.

9. The frequency converter is provided with multiple protective actions to avoid damage of parts.

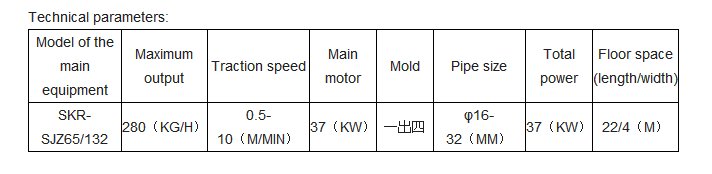

The production line outputs four line pipes through one mold. In addition to high quality of the products produced by it, the production line significantly reduces the equipment cost, factory building cost and production cost, improves the output and shortens the production time. Viewed from its production range, its best production pipe diameter is 16 mm to 40 mm; its total installed power is about 75 KW; its production capacity is 70 percent higher than that of a two-cavities-in-one-mold pipe extrusion production line. The production line comprises a 65/132 double-screw extruder, a set of four-cavities-in-one-mold, a stainless steel vacuum sizing cooler, an ink printer, four tractors, four cutting machines and four material turning frames.

Contact

Supplier