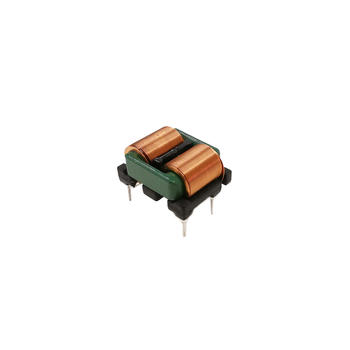

SQ common mode inductor

Model:

sq choke

Size/Color/Thickness:

wire dimension 0.2*1.0mm, inductance 11mh, pin distance 15.5*17mm

MOQ:

1000pcs

Delivery time:

5-7 days

Departure Port:

shenzhen

Sample preparation:

3 days

Certificate:

iso9001, rohs, reach

Payment:

t/t, credit card, western union and so on

Model:

sq choke

Size/Color/Thickness:

wire dimension 0.2*1.0mm, inductance 11mh, pin distance 15.5*17mm

MOQ:

1000pcs

Supplier Info.

Company Name: Donguan Chaorong Electronic Products Co., Ltd.

Registration Date:

2009

Country / Region:

guangdong / China

City:

dong guan

Main Products:

transparent acrylic sheet,epoxy glass fiber sheet,polycarbonate sheet

Product Detail

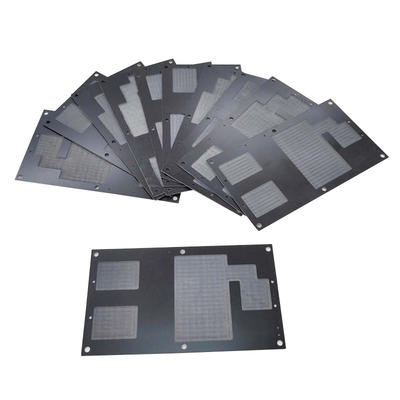

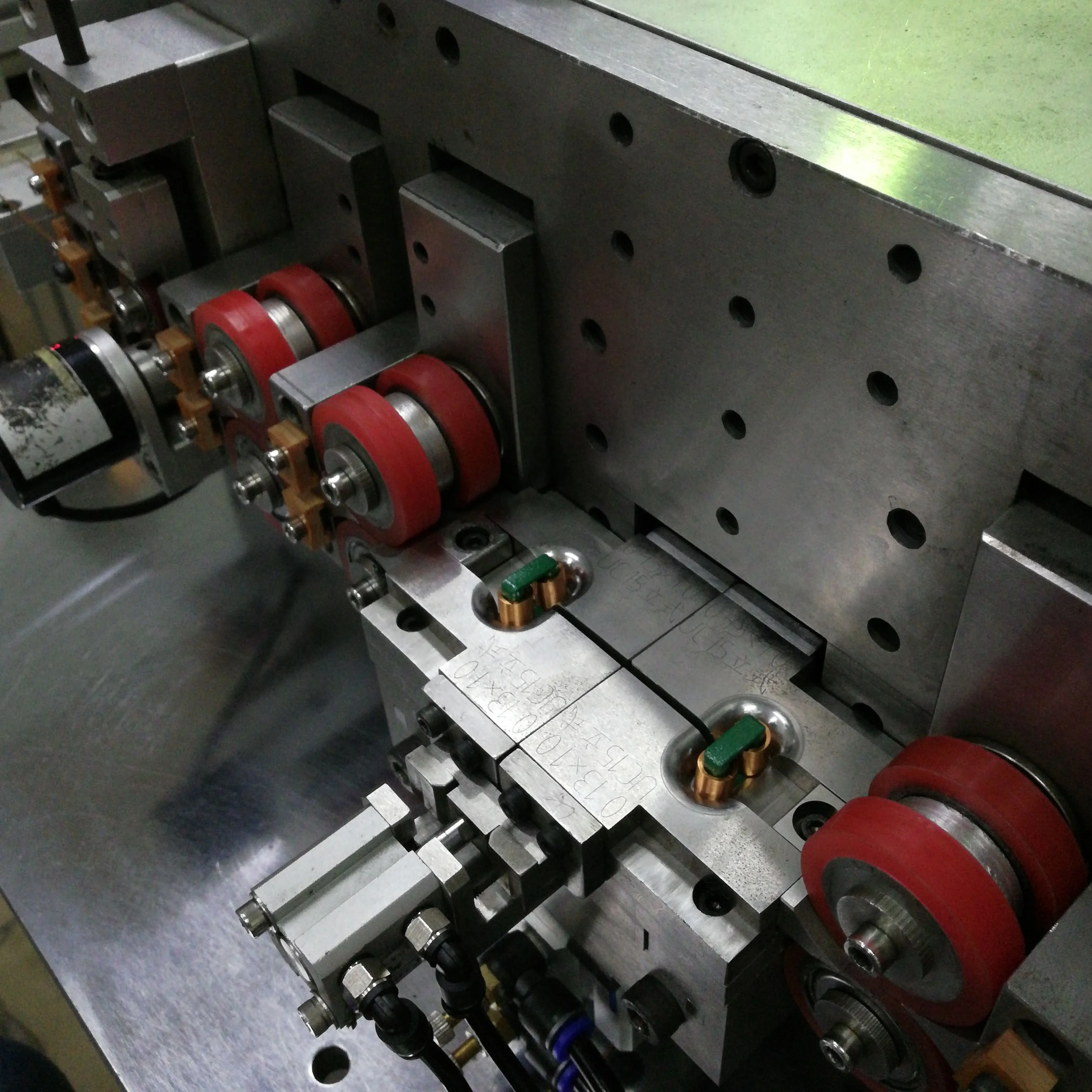

Production procesure

| Coiling copper wires on the magnetic cores by full automation coiling machines |

| Twining copper wires on the bobbin bases |  |

| Gluing the magnetic cores and the bobbin bases together |

| Soldering the common mode chokes with tin by using a phenolic bakelite bar |  |

| Testing the inductance of every choke inductor |

| Putting the choke cores into the blister boxes |  |

| Putting stickers (Item No. and Lot. No.) on every common mode inductor choke |

| Packaging the finished common mode inductors into cartons and ready to be shipped out |  |

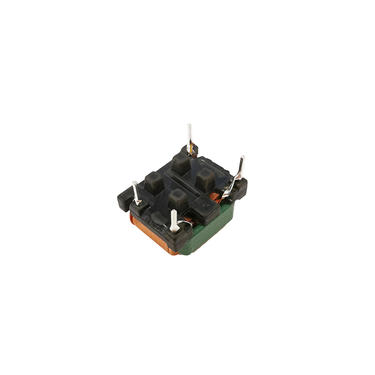

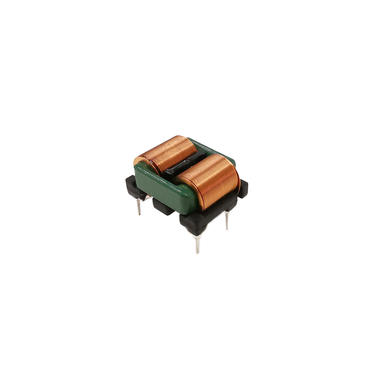

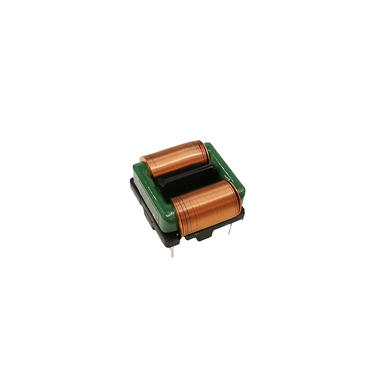

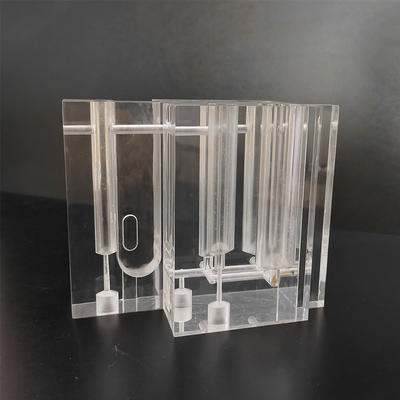

Detailed images

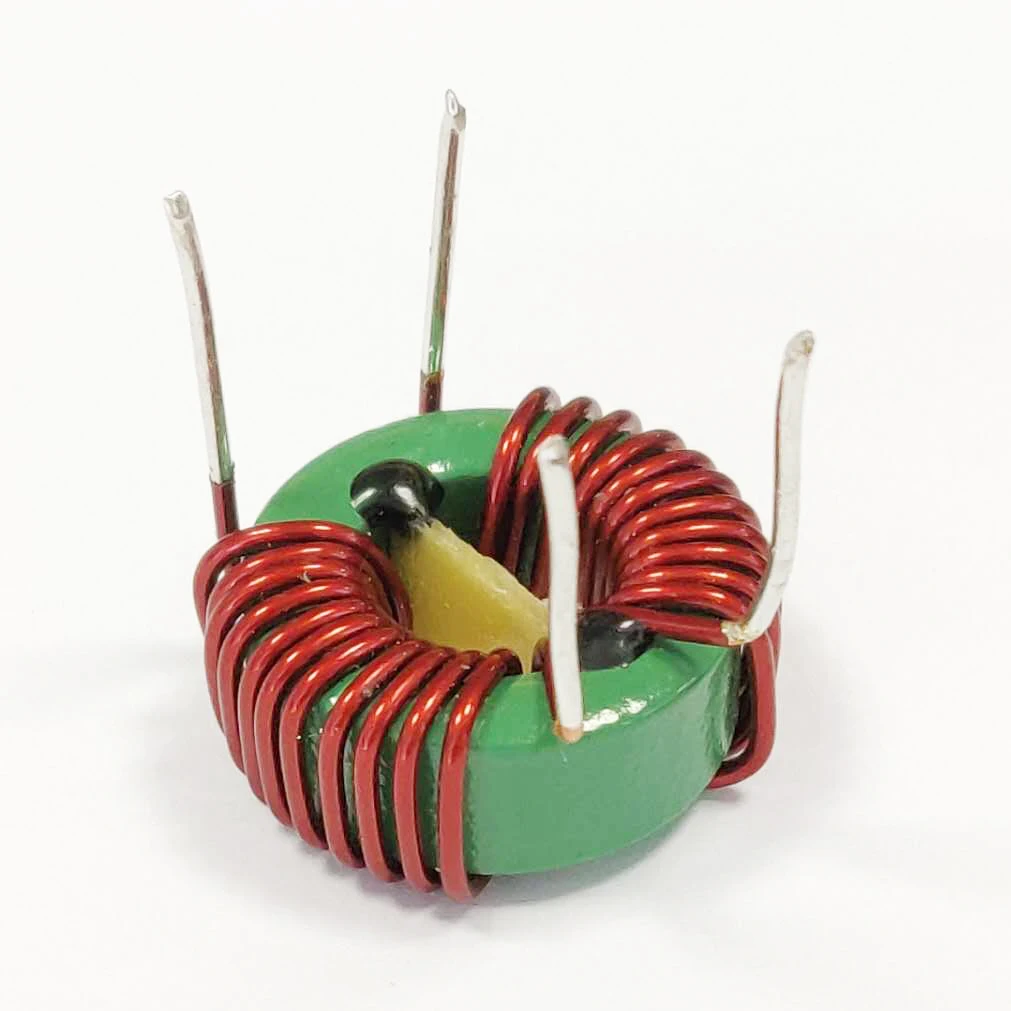

Product Contrast

| Traditional choke | Common mode choke |

|  |

| 1. Handmade twining causing overlapping of the copper wires so the efficiency is low and production cost is high | 1. Auto copper wires coiling without any overlapping hence high efficiency is guaranteed and labor cost also reduces |

| 2. High turn-to-turn capacity, poor impedance and insulation property lead to unsatisfactory EMI | 2. Lower turn-to-turn capacity, better performance in insulation and property. |

| 3. Multiple times of wire twining resulting in poor heat radiation and fast heating-up. | 3. Low temperature coefficient and good performance at heat radiation |

| 4. Due to the influence of conductor skin effect, the conductivity of copper wires would reduce under high frequency. | 4. Excellent conductor skin effect with flat wire under high frequency, the unit current density coule be twice larger than the round wire and the product volume much smaller than the trational choke. |

Application

Common mode chokes are used in the circuit boards in the purpose of reducing radiation, decreasing common mode noise in high frequency, filtering electromagnetic interference signal and so on. They are usually applied in LED lights, halogen lamps, power adaptors, battery chargers, laptops, display devices and the like. Common mode choke inductors are significant in the compose of power supply.

Contact us

Contact

Supplier

Contact us

Tell us your Buying Requirements

You Might Also Like