◪Designed for requirements of spinning frames in textile machinery with convenient installation outside cabinet;

◪Suitable for dusty industrial sites, and the radiator is easy to clean;

◪After the inverter temperature exceeds the set value, it reminds the user to clean the radiator and fan;

◪Easy to operate, single button to stop, being zero on full yarn and wire break;

◪Built-in swing frequency function can output triangle frequency and kick frequency to prevent yarn overlap and facilitate unwinding;

◪Stop automatically to avoid wire break after the pulse feedback signal misses.

Textile Inverter (Spinning Machine/ Bobbiner/ Roving machine/ Circulation machine/ Kniting machine)

Representative Industry

The textile spinning frame can also be used in other industries where dust is frequently cleaned.

Product Overview

V5−BA series is a high-performance vector control inverter launched by V&T for spinning frame in textile industry.

The product adopts the open-loop vector control technology with the current international advanced technology, which has the same excellent control performance with the international high-end inverter, At the same time, it is combined with the use characteristics of textile industry in China, and it further strengthened the reliability and environmental adaptability of the product, as well as the customized and professional design. This greatly meet the needs of textile industry applications.

control method | Open loop vector control |

Power range | 7.5kW~90kW |

Input voltage, frequency | 3AC 380V~480V;50Hz/60Hz |

The output voltage | 3AC 0 ~ rated input voltage |

Output frequency | 0.00~300.00Hz; vector control 1 operation mode 0.0~3000.0Hz can be customized according to customer needs |

Digital input and output | Standard multi-function input terminal, expandable |

Analog input and output | Input: AI1 0~20 mA, input impedance 500Ω, maximum input current 30mA; AI2 Same as above AO2 Same as above |

Pulse input and output | Pulse input: 0.1Hz ~ 50kHz; voltage range: 24V ± 20% |

Protocol | Dual 485 communication interface supports Modbus protocol (RTU), standard operation panel can realize remote control , up to 500 meters |

Brake unit | 15kW and below power section models are built-in; |

External interface | DC24V power source,maximum input current 100 mA |

fan | The standard machine does not have a fan. If you need to add a fan, you can add "−57" to the back of the model. |

DC reactor | Need to be external |

Installation method | Wall mounting |

IP | IP20 |

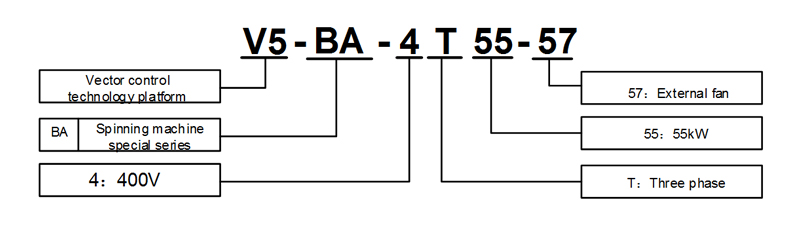

◪V5−BA−4T□□□

Power (kW) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | |

Adapter motor power (kW) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | |

Output | Voltage (V) | 3-phase 0 to rated input voltage | ||||||||||

Rated current (A) | 17 | 22 | 30 | 37 | 44 | 56 | 72 | 91 | 110 | 142 | 176 | |

Overload capability | 115% 1 minute, 160% 0.5 seconds, interval 10 minutes (inverse time characteristic) | |||||||||||

Input | Rated voltage / frequency | 3-phase 380V/480V; 50Hz/60Hz | ||||||||||

Allowable voltage range | 323V ~ 528V; voltage imbalance: ≤ 3%; allow frequency fluctuation: ± 5% | |||||||||||

Rated current (A) | 19 | 26 | 33 | 41 | 48 | 62 | 79 | 100 | 121 | 156 | 194 | |

Brake unit | Built-in as standard | Built-in as optional | ||||||||||

IP | IP20 | |||||||||||

cooling method | Forced air cooling | |||||||||||

Voltage | Model | Three-phase 400V variable torque / light load application | ||

Motor (kW) | Rated output current (A) | Rated input current (A) | ||

400V | V5−BA−4T7.5 | 7.5 | 17 | 27.9 |

V5−BA−4T11 | 11 | 24 | 39 | |

V5−BA−4T15 | 15 | 30 | 50.3 | |

V5−BA−4T18.5 | 18.5 | 37 | 60 | |

V5−BA−4T22 | 22 | 44 | 69.3 | |

V5−BA−4T30 | 30 | 56 | 86 | |

V5−BA−4T37 | 37 | 72 | 104 | |

V5−BA−4T45 | 45 | 91 | 124 | |

V5−BA−4T55 | 55 | 110 | 150 | |

V5−BA−4T75 | 75 | 142 | 190 | |

V5−BA−4T90 | 90 | 176 | 235 | |

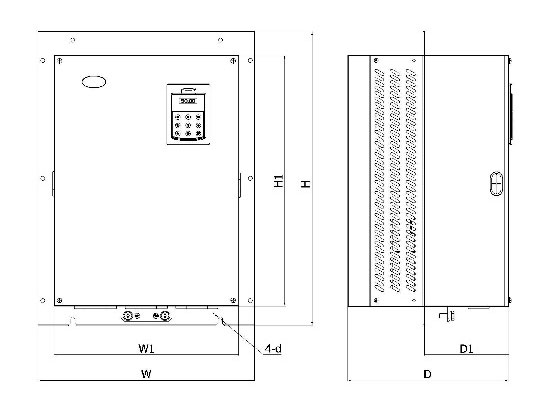

◪Product appearance, installation dimensions, approximate weight

V5−BA Outline and installation dimensions

V5−BA−57 Outline and installation dimensions

◪V5−BA series Outline and installation dimensions and approximate weight

Voltage | Model | Outline and installation dimensions (mm) | weight (kg) | |||||||

W | H | D | W1 | H1 | D1 | W2 | Hole d | |||

V5−BA−4T7.5 | 206 | 303 | 153 | 166 | 251 | 96 | 136 | 8 | 6.5 | |

V5−BA−4T11 | ||||||||||

V5−BA−4T15 | 236 | 386 | 201 | 236 | 318 | 102 | 170 | 8 | 9.5 | |

V5−BA−4T18.5 | ||||||||||

V5−BA−4T22 | 345 | 483 | 238 | 295 | 410 | 130 | 220 | 8 | 18 | |

V5−BA−4T30 | ||||||||||

V5−BA−4T37 | ||||||||||

V5−BA−4T45 | 400 | 610 | 297 | 340 | 520 | 183 | 260 | 10 | 30 | |

V5−BA−4T55 | ||||||||||

V5−BA−4T75 | 470 | 639 | 302 | 410 | 545 | 183 | 320 | 10 | 40 | |

V5−BA−4T90 | ||||||||||

◪V5−BA−57 series Outline and installation dimensions and approximate weight

Voltage | Model | Outline and installation dimensions (mm) | weight (kg) | |||||||

W | H | D | W1 | H1 | D1 | W2 | Hole d | |||

V5−BA−4T7.5−57 | 206 | 303 | 185 | 166 | 251 | 96 | 136 | 8 | 7.5 | |

V5−BA−4T11−57 | ||||||||||

V5−BA−4T15−57 | 286 | 386 | 245 | 226 | 308 | 102 | 170 | 8 | 10.5 | |

V5−BA−4T18.5−57 | ||||||||||

V5−BA−4T22−57 | 345 | 482 | 286 | 285 | 400 | 130 | 220 | 8 | 19 | |

V5−BA−4T30−57 | ||||||||||

V5−BA−4T37−57 | ||||||||||

V5−BA−4T45−57 | 400 | 610 | 343 | 330 | 520 | 183 | 260 | 10 | 31 | |

V5−BA−4T55−57 | ||||||||||

V5−BA−4T75−57 | 470 | 639 | 350 | 400 | 545 | 183 | 320 | 10 | 41 | |

V5−BA−4T90−57 | ||||||||||

◪Option / expansion card

category | name | model | Function Description | reference |

Operation panel | Operation panel (shuttle type) | V6−DP01 | Full range of models | P2−** |

Operation panel (button type) | V6−DP02 | Full range of models | P2−** | |

Text display | EX−MT01 | Man-machine interface - text display | P2−** | |

touch screen | EX−MT02 | Human-machine interface - touch screen | P2−** | |

Fake panel | V6−DP03 | Customer option | P2−** | |

Pallet | V6−DP05 | Operation panel mounting accessories | P2−** | |

Expansion Card | Power monitoring card | EX−PA01 | Three-phase input power supply phase loss / instantaneous power failure monitoring | P2−** |

Phase detection card | EX−PA02 | Three-phase input power phase detection | P2−** | |

External power rectifier card | EX−RF01 | Control power is provided by external power supply | P2−** | |

Programmable CAN bus expansion card | EX−CA05 |

| P2−** | |

Profibus DP communi

cation card | EX−CA06 |

| P2−** | |

Keyboard extension cord | 2 m keyboard extension cable | CB1−200 |

| P2−** |

3 m keyboard extension cable | CB1−300 |

| P2−** |

The main application principle of textile machinery inverter

Features

1.1 reduce costs, reduce costs

Textile mills cannot be separated from air-conditioning equipment. When the air-conditioning motor is controlled by a frequency converter, the power is reduced, and the electricity expenditure is greatly saved. According to data provided by a company, 12 air conditioners can save more than 240,000 yuan of electricity, and the average unit consumption of air conditioners has dropped by 6 or 7 digits.

1.2 Simplified mechanism and improved performance

Controlled by a PLC synchronous controller or industrial computer, and then through a variable frequency governor to achieve synchronous and coordinated operation of multiple motors. The movement of each mechanism is controlled according to the production process curve, and the slenderness simplifies the mechanism. The small roving frame uses AC frequency conversion speed regulation to remove the cone gear transmission mechanism, thereby overcoming the problem of inaccurate slip and speed of the cone gear transmission belt.

As for the spinning frame, the frequency conversion governor is used to remove the forming cylinder in the forming mechanism, which overcomes the phenomenon that the peach bottom is stopped and the peach top is impacted due to the formation of the axial direction. At the same time, the variable speed governor is used to control the speed change of 39 groups of motors to control the number of spindles, so that the spinning of the spun yarn changes in large, medium and small yarns to reduce the yarn breakage rate.

application

AC motors in textile machinery controlled by frequency converters fall into two main categories. One type is the commonly used Y series AC variable frequency motor. This type of motor is mainly used on spinning machines that do not require high precision in speed regulation and have a small speed regulation range. The other is a special inverter for AC variable frequency speed regulation. It is mainly used on machines with high speed regulation accuracy and large speed regulation range.

Inverter

(1) The open-loop control of an asynchronous motor with a frequency converter is called V / F. In this way, the circuit is simple and reliable, but the speed adjustment range is within the range of 10: 1, the speed adjustment accuracy can be 2% to 5%, and the low speed performance is not ideal, so it is mostly used on knitting machines or textile machinery with low requirements .

(2) Adopt speed sensorless vector control inverter. It has excellent low-speed characteristics, simple circuit structure, high reliability, and also has better addition and subtraction characteristics, voltage characteristics, and current limit characteristics. The speed regulation accuracy can reach 0.5% ~ 1.0%, and the speed regulation range is within the range of 20: 1, which is more suitable for the speed regulation of printing and dyeing machinery.

(3) Adopting vector variable frequency control asynchronous motor with speed feedback, closed-loop variable frequency speed regulation, also known as AC servo motor, speed regulation range can reach 100: 1. In order to increase the switching frequency of the inverter, a power insulated gate bipolar transistor (high-frequency response, advanced, and intelligent) is applied. It is suitable for slitting warping machines with high speed and constant tension and constant line speed, and sizing. Machines, heat setting machines and chemical filament spinning equipment.

On some equipment, such as Barmag high-speed length heads and DLENES high-speed heat rollers, the required electrical components are integrated with the inverter and the control panel with the corresponding head mechanical parts, which has reduced the volume. Enhanced reliability.

Contact

Supplier