◪wide input voltage range: When the inverter is fully loaded, the input voltage range is 320 ~ 480V.

◪strong anti-interference capability: Multiple inverter are installed in the same electric control cabinet with non-interference at strictly international EMC standard design.

◪Strong environment adaptiveness: The environment of stone processing is very bad with two much dust on site ,and it is easy to be not good heat dissipation or fan blocked.

◪Excellent vector control: Strong torque under low frequency, high stability and precision, greatly meet the needs of the stone industry.

Variable Frequency Drive for Stone Processing

Representative Industry

Gantry Stone Saw, Rope Saw and so on

Product Overview

V5-H-C8 series is a special inverter with high-performance vector control for the stone industry launched by Shenzhen V&T Technologies Co.,Ltd, which is widely used in equipment such as rope saws and frame saws.The product has the same excellent control performance with the international high-end inverter. At the same time, it is combined with the use characteristics of China, and it further strengthened the reliability and environmental adaptability of the product, as well as consider this field’s features and client’s requirements. This greatly meet the needs of various transmission applications in stone industry.

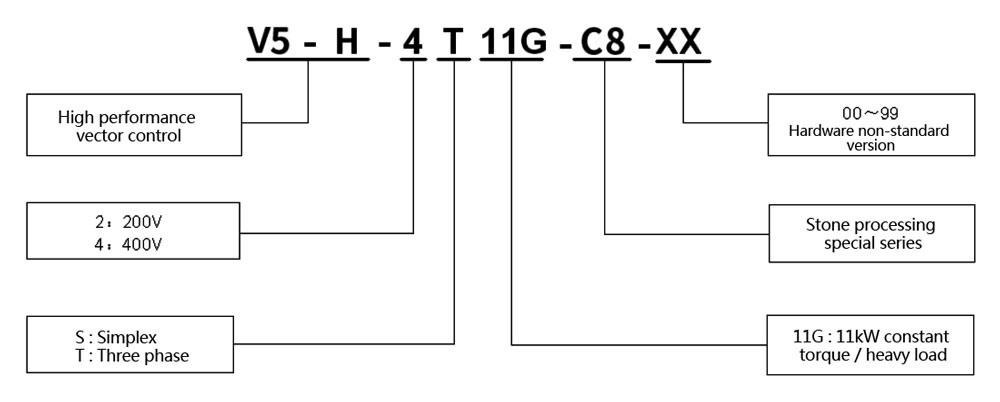

◪V5−H−4T□□□G−C8 3 Phase 400V Constant Torque/Heavy-duty Applications

Power(kW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | |||

Motor(kW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | |||

Output | Voltage(V) | 3 phase 0~Rated Voltage | ||||||||||||||||

Rated Current(A) | 2.5 | 3.8 | 5.5 | 9 | 13 | 17 | 24 | 30 | 39 | 45 | 60 | 75 | 91 | 112 | 150 | |||

Overload capacity | 150% 1min,180% 10 second, 200% 0.5 second,interval: 10 minutes (inverse time lag feature) | |||||||||||||||||

Input | Voltage/ frequency | 3 phase 380V~480V;50Hz/60Hz | ||||||||||||||||

Allowable voltage range | 323V~528V;Voltage imbalance:≤3% ;allowable frequency fluctuation:±5% | |||||||||||||||||

Rated Current(A) | 3.5 | 6.2 | 9.2 | 14.9 | 21.5 | 27.9 | 39 | 50.3 | 60 | 69.3 | 86 | 104 | 124 | 150 | 201 | |||

Braking unit | Built-in as standard | Built-in as optional | ||||||||||||||||

IP | IP20 | |||||||||||||||||

Cooling mode | Natural air cooling | Forced air cooling | ||||||||||||||||

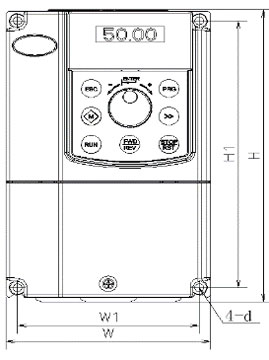

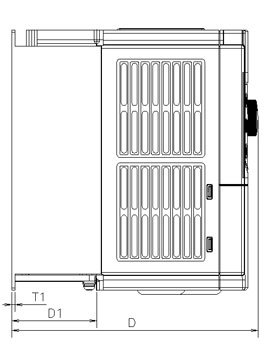

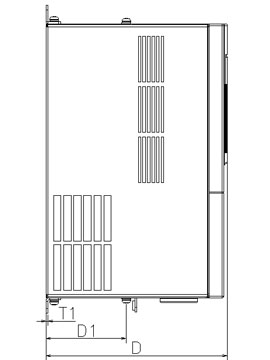

◪Product appearance, installation dimensions, approximate weight

V5−H−4T7.5G−C8 and lower power grade

V5-H-4T11G−C8 and higher power grade

◪Product appearance, installation dimensions, approximate weight

Voltage | Model | Appearance, Installation Dimensions(mm) | Weight (kg) | |||||||

W | H | D | W1 | H1 | D1 | T1 | Hole d | |||

400V | V5−H−4T0.75G−C8 | 118 | 190 | 155 | 105 | 173 | 40.8 | 3 | 5.5 | 1.5 |

V5−H−4T1.5G−C8 | 118 | 190 | 175 | 105 | 173 | 60.5 | 4 | 5.5 | 2.6 | |

V5−H−4T2.2G−C8 | ||||||||||

V5−H−4T3.7G−C8 | ||||||||||

V5−H−4T5.5G−C8 | 155 | 249 | 185 | 136 | 232 | 69 | 8 | 5.5 | 4.5 | |

V5−H−4T7.5G−C8 | ||||||||||

V5−H−4T11G−C8 | 210 | 337 | 200 | 150 | 324 | 88 | 2 | 7 | 8.5 | |

V5−H−4T15G−C8 | ||||||||||

V5−H−4T18.5G−C8 | 289 | 440 | 215 | 200 | 425 | 88 | 2.5 | 7 | 17 | |

V5−H−4T22G−C8 | ||||||||||

V5−H−4T30G−C8 | ||||||||||

V5−H−4T37G−C8 | 319 | 575 | 212 | 220 | 553 | 90.5 | 2.5 | 10 | 25 | |

V5−H−4T45G−C8 | ||||||||||

V5−H−4T55G−C8 | 404 | 615 | 250 | 270 | 590 | 86.5 | 3.0 | 10 | 35 | |

V5−H−4T75G−C8 | ||||||||||

The following two points should be kept in mind when applying stone processing inverters:

(1) Use environment. Inverter has higher requirements for ambient temperature, and it is also a device with large heat generation. When using high-power inverters in stone processing, when considering cooling, we must consider the heat of the inverter. Generally, according to the capacity of the inverter, 3 to 4% of the power is calculated by the calorific value of the inverter. . The rated capacity of the inverter in the stone processing industry is marked for a certain use environment. The inverter's operating temperature is generally required to be 0 ° C to 55 ° C, preferably controlled below 40 ° C, and the relative humidity should be controlled to 20% to 90%. .

The rated current of the inverter in the stone processing industry is based on a certain altitude, rated voltage, and rated carrier frequency. If it exceeds the regulations, it will cause the inverter to be derated. In the selection of inverter for stone processing, the capacity should be modified as follows: when the altitude is higher than 1Km, the inverter rated current should be reduced by about 6% for each additional 1Km; when the input voltage is increased by 2%, the inverter rated current It should be corrected downward by 4%. When the carrier frequency is higher than the rated carrier frequency, the rated current should be corrected accordingly.

(2) External configuration of inverter for stone processing industry. In order to prevent operating overvoltage, it is not suitable to install a contactor between the inverter and the motor. If there is no fast fuse before the internal rectifier circuit of the inverter, a fast fuse that meets the requirements should be externally installed between the inverter and the power supply. An air circuit breaker cannot be used. Instead of fuse

Contact

Supplier