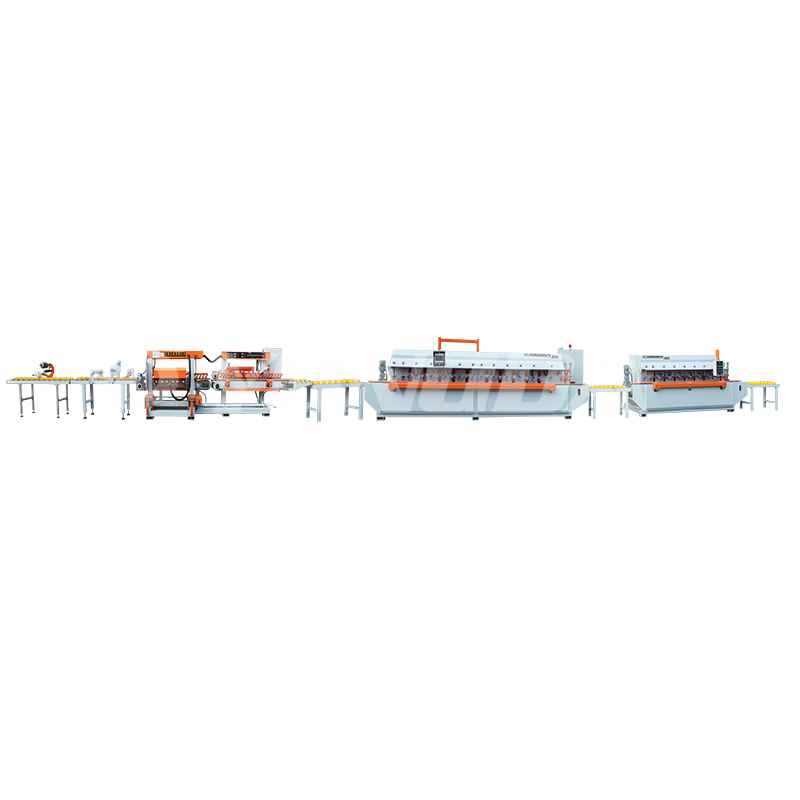

YXT-200Ⅱ automatic stone profiling line

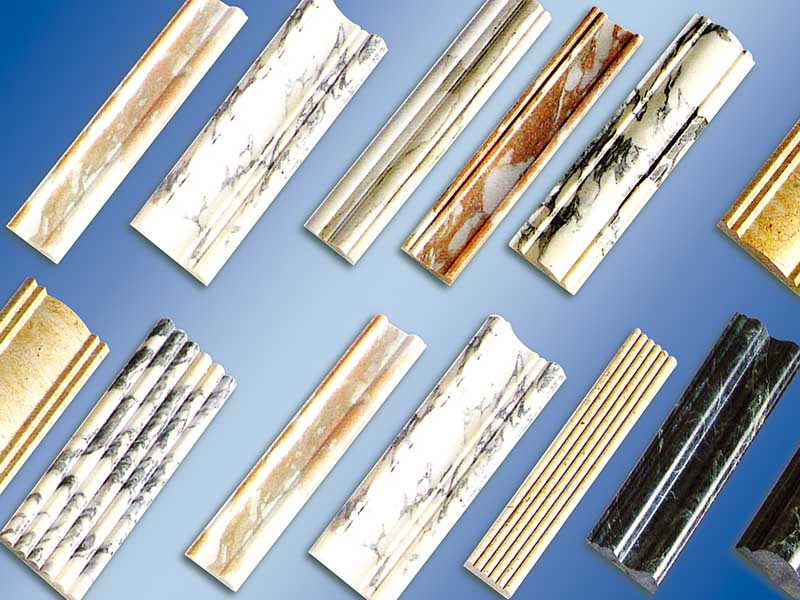

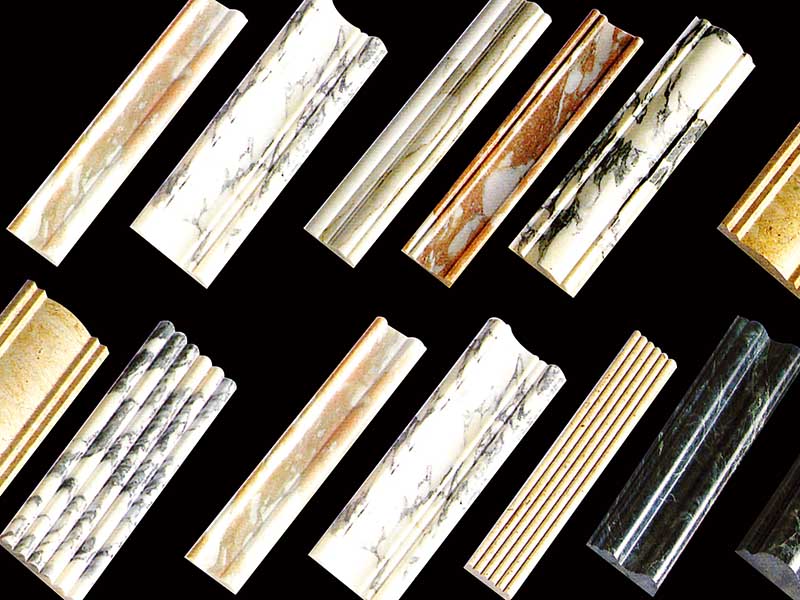

In 2000,YONGDA started to invest into developing stone profiling line and achieved in 2002. This is the first automatic stone profiling line in China. From then on, our machine has gained much good evaluation from our largest customers such as Best Cheer, UMGG, KangLi, XiShi, YingLiang, BaoYun, ChuanQi, HaoTing, WangFeng, WangFang,etc.

By the end of 2012,we finished developing the YXT-200Ⅱ automatic stone profiling line based on the experience of the first generation successfully. And we have expanded the functions of the machine with Automatic Tool Correcting and Romote Control.

AUTOMATIC TOOL CORRECTING FUNCTION

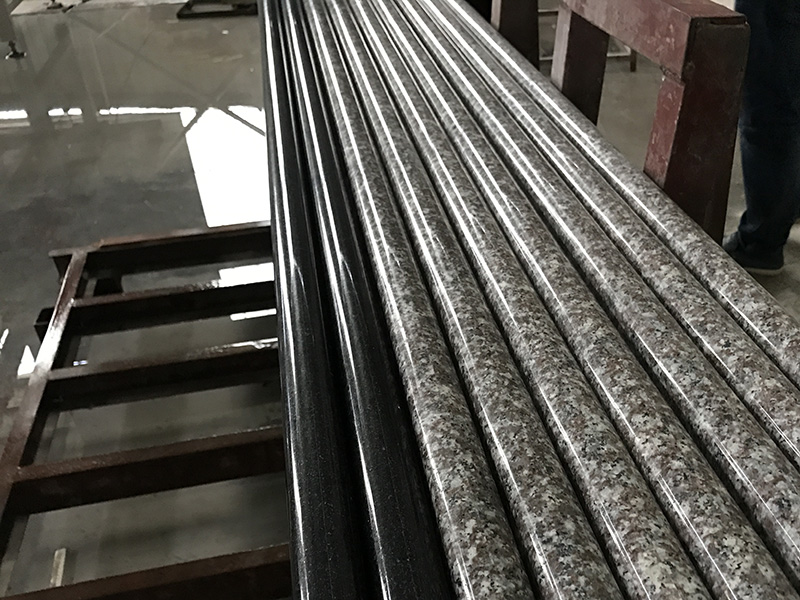

For a long time, because the precision production line machine polishing wheel is not guaranteed, resulting in the polishing wheel arrangement must be adjusted to the same line through the manual, the past takes several hours to put all the polishing wheel roughly tune into a straight line, is not accurate in the same line, via slowly running a few minutes of stone when polishing lines, so that not only waste line material, a waste of time, quite troublesome. The YXT-200 II automatic tool line polishing production line successfully solves the thorny problem that the line machine is difficult to knives. The automatic tool setting function can automatically and accurately adjust all polishing wheels in the same straight line in 5 minutes, fast and accurate. This function is a domestic first, and has obtained the Chinese national patent, is an important breakthrough in the line machine technology, is the past can not become possible.

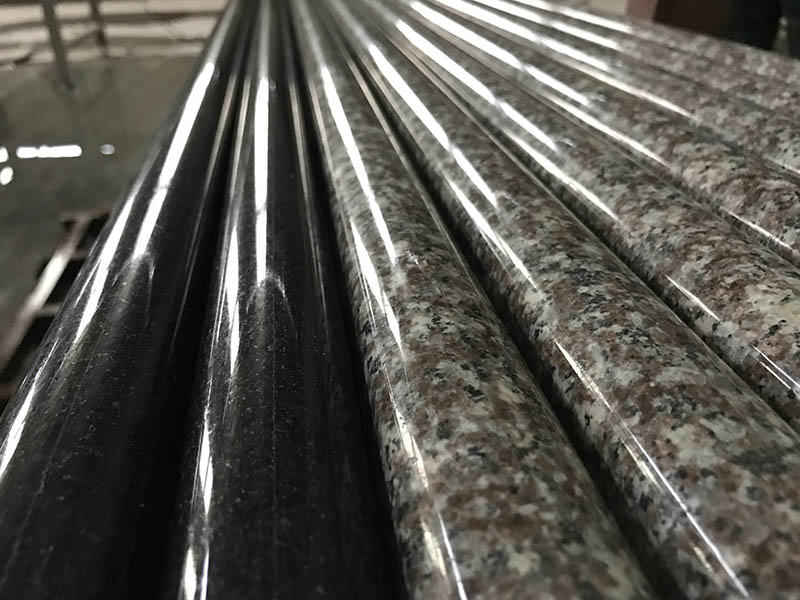

INTELLIGENT SOFTWARE HUMANIZED CONTROL TECHNOLOGY

The process of line polishing is very demanding for the dynamic balance of the polishing wheel, otherwise it is easy to produce strong vibration to affect the polishing quality and even to break the plate. After 10 years of accumulation and research experience, Yongda independently developed a set of intelligent software, scientific and accurate calculation of the polishing process required pressure and intelligent control, with self-locking function, so as to control the polishing process is more accurate and more stable and reliable.

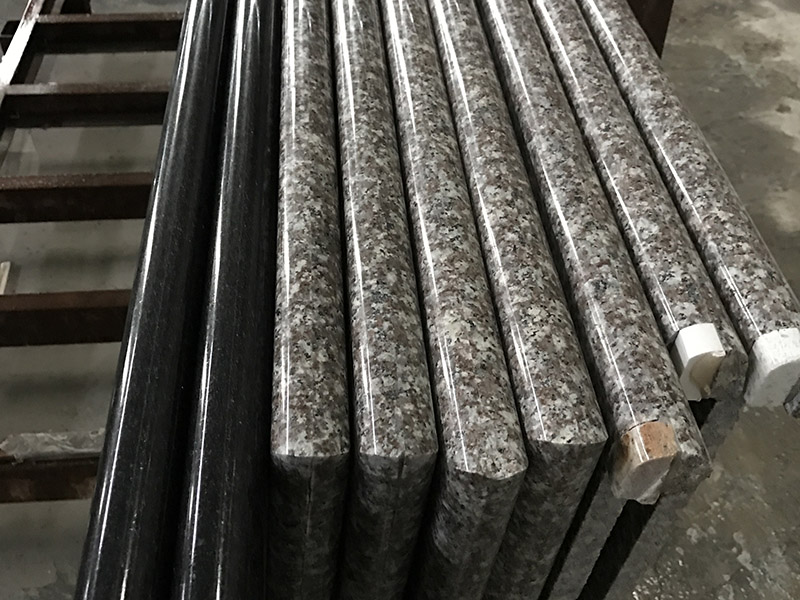

REMOTE CONTROL FUNCTION

The wireless transmission and receiving technology used in the control of the machine which is not obstructed by the obstacles, the signal is stable and reliable, remote control small size and easy to carry. In the past, two people must be controlled when lifting the grinding wheel. One observes the lifting of the grinding wheel, and the other operates the control button. Controlled by the remote control when a wheel lift sufficient! And can be zero-distance observation of any wheel or lift the precise conditions of access, both to save manpower and greatly improve production efficiency and production quality. The remote control can also realize the remote control of the line machine anywhere within 50 meters from the line machine, and can react more quickly once the equipment abnormality is found.

Items | Unit | YXT-200Ⅱ/YXT-200 |

nos of shaping wheel | pc | 4 |

dia of shaping wheel | mm | 200 |

nos of polishing wheel | pc | 8 |

dia of polishing wheel | mm | 200 |

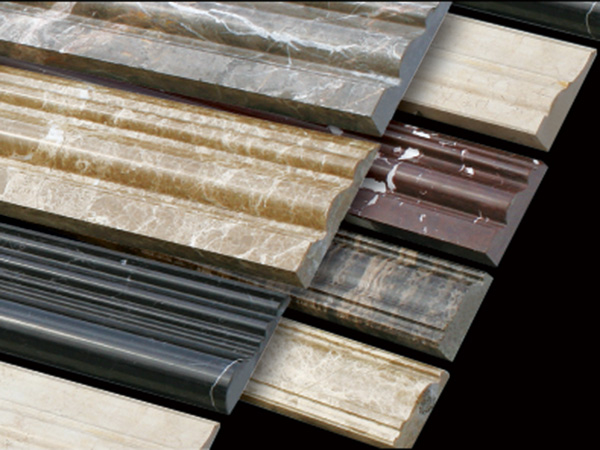

working width | mm | 20~200 |

working thickness | mm | 15~120 |

working speed | m/min | 1~4 |

total power | kw | 85 |

water comsumption | L/min | 200 |

air consumption | L/min | 10 |

outer dimension | mm | shaping :4200×1600×1900; polishing:5700×1600×1900 |

total weight | kg | 8000 |

For a long time, because the precision production line machine polishing wheel is not guaranteed, resulting in the polishing wheel arrangement must be adjusted to the same line through the manual, the past takes several hours to put all the polishing wheel roughly tune into a straight line, is not accurate in the same line, via slowly running a few minutes of stone when polishing lines, so that not only waste line material, a waste of time, quite troublesome. The YXT-200 II automatic tool line polishing production line successfully solves the thorny problem that the line machine is difficult to knives. The automatic tool setting function can automatically and accurately adjust all polishing wheels in the same straight line in 5 minutes, fast and accurate. This function is a domestic first, and has obtained the Chinese national patent, is an important breakthrough in the line machine technology, is the past can not become possible.

Humanized control technology of intelligent software

Line polishing process for balancing the polishing wheel demanding, or prone to strong vibration impact polishing quality or even broken plate. After more than 10 years of accumulated experience and research, Yongda independently developed a set of intelligent software that scientifically and accurately calculates the pressure needed for the polishing process and intelligently adjusts it. Together with the self-locking function, it controls the entire polishing process more precisely and stably, more reliable.

The automatic tool setting function can automatically and accurately adjust all polishing wheels in the same straight line in 5 minutes, fast and accurate. This function is a domestic first, and has obtained the Chinese national patent

Yongda independently developed a set of intelligent software that scientifically and accurately calculates the pressure needed for the polishing process and intelligently adjusts it. Together with the self-locking function, it controls the entire polishing process more precisely and stably, more reliable.

Technology hotline:7*24 for service full-time

Engineers :7*24 for service

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts