Electrommunication product by injection molding

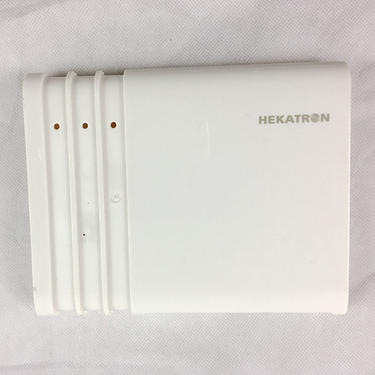

| Part Name: | Gateway |

| Part size: | 175*136*32mm |

| Raw Material: | ABS+PC |

| Color: | RAL9010,White |

| Mould Cavity No.: | 1*1 |

| Injection gate: | Hot runner with pin point gate |

| Surface finished: | Mirror Polishing |

| Core &Cavity steel: | 1.2344,hardness 48~52HRC |

| Mold component standard: | HASCO or equivalent |

| Injection machine size: | 180T |

| Cycle time: | 35S |

| Mold life: | 300000 shots |

| Customer: | HEKATR@N |

| Export: | Germany |

We carried out first trial shot on 40th day,little longer than planed.Since YUDO hot runner system came out of expected date,one week late.Three trial shots for samples production,and finished whole project in 50days.Manufacture schedule,samples delivery and mold shipment date ran as planing,within customer’s request.

Both parts critical surface need in high polishing,mirror grade,no any marked or scratch allowed.When production,have to take out by robot hand,and cover PE film for protection.

Silkscreen also made by EMM factory.

At first trial shot,case part came out with obvious sink mark and scratch on side surface.

The ribs inside are too thick cause sink mark,and no draft angle on side surface cause scratch when mold open.Finally We cut rib material solved sink mark problem.But no draft angle allowed on side surface,we had to add two sliders on both side,to ensure all outside surface look glossy.

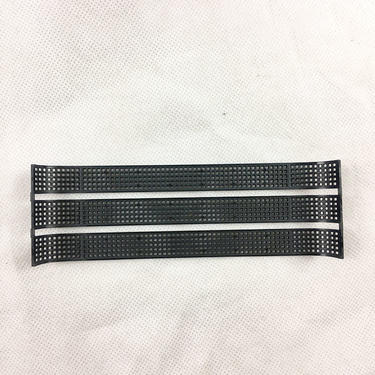

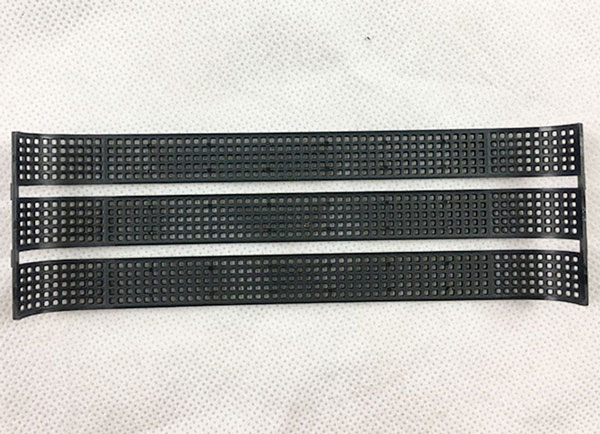

The grid part has many small window and only 0.6mm thick.We found flowing mark at each window corner and short shot problem at first trial shot.Then we suggested change high polishing surface to fine texture,VDI3400-33,also change injection gate location,from both side for filling.Customer confirmed and part came out look good.

Contact

Supplier