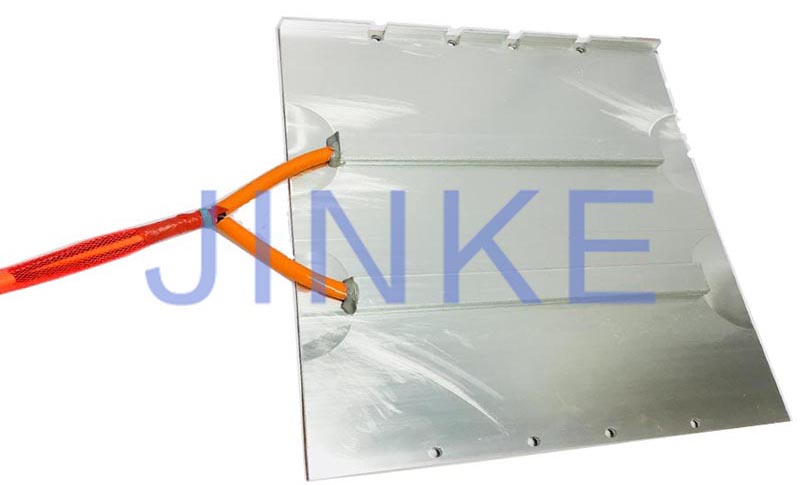

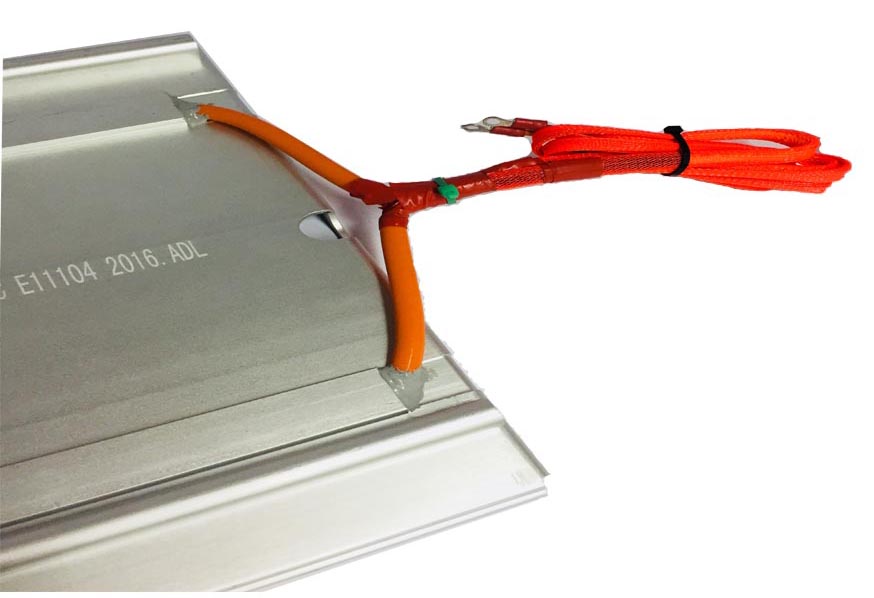

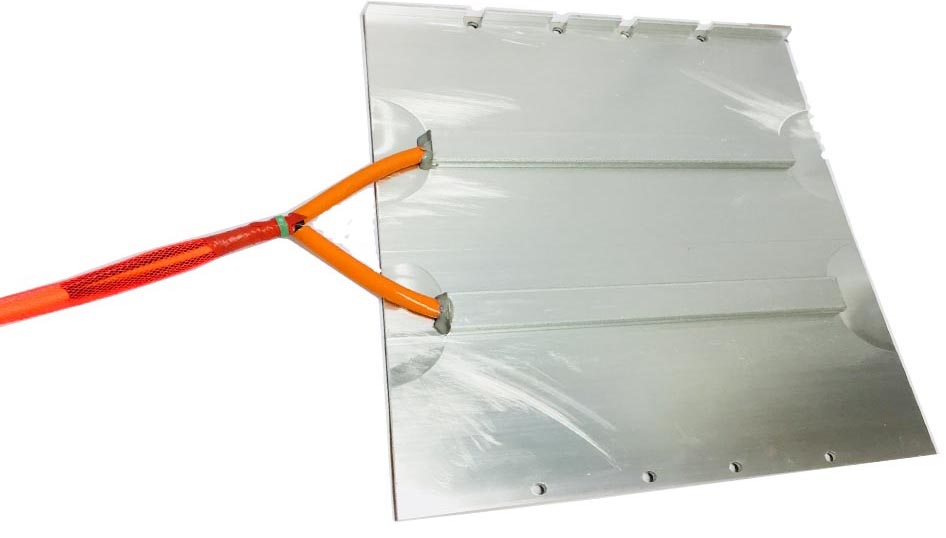

High Efficiency PTC Heating Element For Battery

2. Quickly start at ultra-low temperature and heating quickly.

3.High resistance inrush current, long life

4. Good performance in insulation and leakage current is low.

5.The appearance can be customized based on customer requirements.

2.Rated voltage: AC/DC 48V, 100V,110V,115V-240V

3.Operating life: up to 1,000 times

❈ APPLICATION

new energy vehicle

❈ PRODUCT PACKAGING

❈ Faq

What is your minimum order quantity?

At least 1000pcs for each item.

What is the delivery period?

About 20-25days, it is up to your order quantity.

What is your payment term?

T/T(30% before production and 70% before shipment),L/C,D/A, D/P, T/T, Western Union, MoneyGram, OA

Can you send free samples?

We can send free samples.

What is your shipping ways?

For sample we usually send by DHL, FEDEX, UPS, THT, EMS(taking 5-7business days). For mass product we are shipping by sea or by air.

1. What are the main applications of polymer PTC thermistors?

Polymer PTC thermistors can be used in computers and their external equipment, mobile phones, battery packs, telecommunications and network equipment, transformers, industrial control equipment, automobiles and other electronic products to play an overcurrent or overtemperature protection role.

2. What is the working principle of polymer PTC thermistors?

The polymer PTC thermistor is made of a polymer material filled with carbon black particles. This material has a certain electrical conductivity, so it can pass the rated current. If the current through the thermistor is too high, its heating power is greater than the heat dissipation power. At this time, the temperature of the thermistor will begin to rise continuously, and the polymer matrix in the thermistor will begin to expand, which will cause the carbon black particles to separate. And cause the resistance to rise, thus reducing the current in the circuit very effectively. At this time, a small current still flows in the circuit, and this current keeps the thermistor at a sufficient temperature to maintain a high resistance state. After the fault is removed, the polymer PTC thermistor cools down quickly and will return to the original low resistance state, so it can work again like a new thermistor.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts