WHY Maydos? ![]()

Capable — Top 5 manufacturer in China! Biggest factory in Asia!

Professional — 10 years' experience for export!

Eternal — Stable quality and price!

Supportable — Overseas technical support and return visit after sale!

Description:

Maydos Chloroprene Rubber Adhesive is a multi-purpose contact adhesive with strong bonding ability. It is made with up-to-date technology and equipment and has super viscidity and long service life.

Advantages:

1. Fast bonding speed, excellent and long lasting bonding power.

2. Compare with conventional adhesives, the difference is obvious (excellent) when bonding fireproof board,

aluminum-plastic board and PVC board.

3. Good protective properties after hardening: anti oil, acid and alkali and impact resistant. Effectively prolong the

service life of bonding objects.

4. Extra heat and cold resistant after hardening: Endurable when temperature is between -50℃ and 100℃.

Where to Use:

Suitable for industries such as architectural decoration, furniture manufacture, automobile, packaging, advertising, shoes, leather, rubber, textile, toy, and home decoration. It can be widely used for both hard-to-contact materials like anti-firing plate, aluminum-plastic plate and PVC board, and common board like wood board, plywood, wood floor, furniture, wallpaper, polyester plywood, bamboo board, asbestos board, carpet etc.

Technical Data:

Appearance: Light yellow viscous liquid

Viscosity: 77-90 Ku / 30℃

2000-3000 Mpa. S/25℃

Solids Content: 18%-25%

Shear Strength:

30 minutes: ≥0.7mpa

48 hours: ≥1.7mpa

Specific Gravity: 0.856kg/L

VOC: ≤750 g/L

Dosage: 195-250g/m2

Shlef Life:

12 months in sealed tins.

Packing Size:

0.5kg, 0.8kg, 2.2kg, 3kg, 15kg, 180kg.

Application Tools:

Brush, scraper etc.

Application Method:

1. Surface preparation: Bonding surface should be dry, clean and free of dust and rust. Smooth surface such as

plywood, rubber, must be sanded first to make it coarse. After that, clean the surface and apply the adhesive.

2. Gluing: Mix up the adhesive before use. Pour adhesive on the two bonding surfaces separately and spread it

with brush or scraper. To achieve the best bonding performance, the application should be done toward the

same direction and evenly.

3. Airing: After application of the adhesive, enough time should be given to let the solvent evaporate completely to

avoid bubble or stickiness.

4. Bonding: The application should be done once and for all. Aim the two surfaces, bond together and press. Don’t

move the two surfaces back and forth, or the bonding effect will be weakened.

Storage:

Keep it out of touch of children and store in cool, dry and ventilated place. The storing temperature shall range from 5 - 35 Celsius, and the relative humidity shall be<80%.

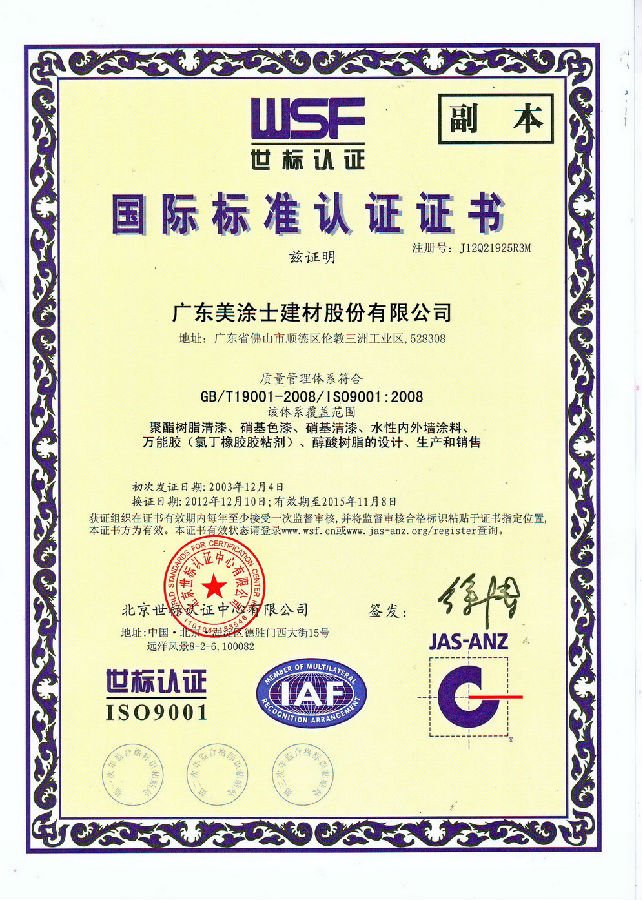

Certificates:

Contact

Supplier