Features of GOODWELD IF Spot Welding Machine Controller:

1.Three-phase 380V input; DC control; 1KHZ control frequency; 1ms welding time control; waveform can be adjusted.

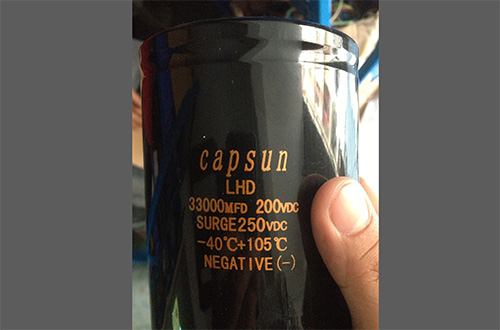

2. Imported German Infineon modules, British capacitor electronic components. Effective guarantee of reliable quality.

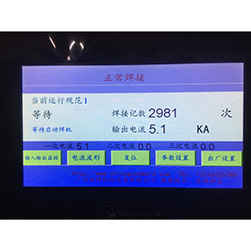

3. Touch screen operation is simple and generous. 99 welding procedures are available. 1 to 99 welding current options. Three-stage welding modes: firstly preheating, secondly welding, and thirdly tempering; among them, the welding interface can self define the specifications of increment and decrement, as well as keeping, maintaining, cooling, rest, and counting solder joints.

4. IF controller's dual communication ports (RS485 and RS232) realize real-time communication. Using modBUS standard protocol, the welding speed is faster.

5. Real-time detection and display of current waveforms, with current monitoring references and records, can be used for automated detection.

6. Balanced three-phase input; small impact on the grid network pressure; high power factor can obtain more than 90% of the power value; less loss. Bunching effect due to the energy concentration of the IF inverter spot welding machine.

7. Welding procedure of welding aluminum plate and galvanized steel plate with IFDC spot welding machine.

After welding the aluminum plate or galvanized steel plate with the controller of IF spot welding machine, not only a beautiful appearance can be ensured, but also minor damage of the galvanized layer and the oxidized layer can be found with such small welding spatter. Apart from this, less wear result of the welding tip electrode can be found.

Development And Customization Inverter Welding Controller Inverter Welding Transformer

The IF controller includes a power driver board, a rectifier module part, a capacitor board filter board, a high-power IGBT, and a motherboard center control part.

Goodweld Product Show

IF Spot Welding Machine Controller HWIN-800A

IF Spot Welding Machine Controller HWIN-800A IF Spot Welding Machine Controller HWIN-800B

IF Spot Welding Machine Controller HWIN-800B IF Spot Welding Machine Controller HWIN-800C

IF Spot Welding Machine Controller HWIN-800C IF Spot Welding Machine Controller HWIN-800D

IF Spot Welding Machine Controller HWIN-800D IF Spot Welding Machine Controller MF2-100A

IF Spot Welding Machine Controller MF2-100A IF Spot Welding Machine Controller MF2-200A

IF Spot Welding Machine Controller MF2-200A IF Spot Welding Machine Controller Display 1

IF Spot Welding Machine Controller Display 1 IF Spot Welding Machine Controller Display 2

IF Spot Welding Machine Controller Display 2Goodweld Configure Show

Advantages & Parameter

Advantages of IF Spot Welding Machine Controller:

1. The welding frequency of the IF spot welding machine controller is 1000Hz, which is 20 times higher than the previous power frequency 50/60HZ. From the original pulse width of the AC waveform into a stable constant current DC waveform, it better controls current accuracy, provides more stable power supply frequency and output voltage, realizes faster welding speed and makes material deformation smaller.

2. After the IF spot welding machine controller is combined with the IF spot welding machine transformer, the power factor will be higher, the loss will be smaller, and the energy saving will be more than 40%.

3. The use of an IF spot welder controller will increase the electrode life by more than 5 times.

4. IF spot welding machine controller combined with IF transformer is particularly suitable for welding galvanized steel plate, aluminum plate, copper plate line, multi-layer steel plate, heterosexual metal, etc.

5. IF controller is suitable for the industry: aerospace, automotive parts, ship military, home appliances hardware, electronic appliances, building materials and so on.

Model | Rated output | Power Supply | Core Control | Communication | Call Welding |

HWIN-300 | 300 |

50/60HZ AC+10% Operating temperature 10 degrees -60 degrees. Water is needed. |

|

|

|

HWIN-450 | 450 | ||||

HWIN-600 | 600 | ||||

HWIN-900 | 900 | ||||

HWIN-1400 | 1400 | ||||

HWIN-1600 | 1600 | ||||

HWIN-1800 | 1800 | ||||

HWIN-2400 | 2400 | ||||

HWIN-2800 | 2800 | ||||

HWIN-3600 | 3600 | ||||

HWIN-4800 | 4800 |

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts